1

MIOSHA-STD-1303 (03/21)

16 Pages

For further information

Ph: 517-284-7740

www.michigan.gov/mioshastandards

DEPARTMENT OF LABOR AND ECONOMIC OPPORTUNITY

CONSTRUCTION STANDARD

Filed with the Secretary of State on August 31, 1976 (as amended November 21, 1980)

(as amended November 23, 1982) (as amended May 17, 1983) (as amended September 10, 1985)

as amended January 11, 1988) (as amended September 3, 1996) (as amended July 12, 1999)

(as amended March 14, 2013) (as amended March 10, 2014) (as amended March 24, 2015)

(as amended November 9, 2016) (as amended March 16, 2021)

These rules take effect immediately upon filing with the secretary of state unless adopted under section 33, 44, or

45a(6) of the administrative procedures act of 1969, 1969 PA 306, MCL 24.233, 24.244, or 24.245a.

Rules adopted under these sections become effective 7 days after filing with the secretary of state.

(By authority conferred on the director of the department of labor and economic opportunity by sections 14, 16, 19,

21, and 24 of the Michigan occupational safety and health act, 1974 PA 154, MCL 408.1014, 408.1016, 408.1019,

408.1021, and 408.1024, and Executive Reorganization Order Nos. 1996-1, 1996-2, 2003-1, 2008-4, 2011-4, and

2019-3, MCL 330.3101, 445.2001, 445.2011, 445.2025, 445.2030, and 125.1998)

R 408.40601, R 408.40615, R 408.40616, R 408.40617a, and R 408.40636 of the Michigan Administrative Code

are amended, and R 408.40624a is rescinded, as follows:

PART 6, PERSONAL PROTECTIVE EQUIPMENT

Table of Contents:

R 408.40601 Scope, adoption, and availability............ 2

R 408.40614 Definitions, C to F. .................................. 2

R 408.40615 Definitions, H to R. ................................. 2

R 408.40616 Definitions, S, T. ..................................... 3

R 408.40617 Employer’s and employee’s

responsibilities. ...................................................... 3

PAYMENT FOR PERSONAL PROTECTIVE

EQUIPMENT ......................................................... 3

R 408.40617a Payment for personal protective

equipment (PPE). .................................................. 3

FOOT AND TOE PROTECTION ................................. 4

R 408.40625 Foot and toe protection. ......................... 4

HAND AND BODY PROTECTION .............................. 4

R 408.40626 Hand and body protection. ..................... 4

FALL PROTECTION ................................................... 4

R 408.40631 Fall protection. ........................................ 4

R 408.40636 Working over or near water. ................... 4

1926.28 - Personal Protective Equipment .................... 5

1926.97 – Electrical Protective equipment ................... 6

1926.100 - Head Protection ....................................... 13

1926.102 - Eye and Face Protection .......................... 14

1926.105 – Safety Nets .............................................. 15

2

R 408.40601 Scope, adoption, and availability.

Rule 601. (1) This standard provides specifications

for personal protective equipment and prescribes the

use, selection, and maintenance of this equipment for

the protection of the employee’s head, face, eyes,

hands, feet, and body during construction operations.

(2) Hearing protection must be in compliance with

Occupational Health Standard Part 680. “Occupational

Noise Exposure.”

(3) Respiratory protection must be in compliance with

General Industry and Construction Safety and Health

Standard Part 451. “Respiratory Protection.”

(4) Protective equipment, including personal protective

equipment for eyes, face, head, hands, feet, and body,

protective clothing, and protective shields and barriers,

must be provided, used, and maintained in a sanitary

and reliable condition wherever it is necessary by

reason of hazards of processes or environment,

chemical hazards, radiological hazards, or mechanical

irritants encountered in a manner capable of causing

injury or impairment in the function of any part of the

body through absorption, inhalation, or physical contact.

(5) The following federal Occupational Safety and

Health Administration (OSHA) regulations are adopted

by reference in these rules:

(a) 29 CFR 1926.28 “Personal protective equipment,”

as in effect as of the effective date of these rules.

(b) 29 CFR 1926.100 “Head protection,” as amended

July 23, 2012.

(c) 29 CFR 1926.102 “Eye and face protection,” as

amended March 25, 2016.

(d) 29 CFR 1926.97 “Electrical protective equipment,”

as amended July 10, 2014.

(e) 29 CFR 1926.105 “Safety nets,” as amended

August 2, 1995.

(6) A reference to 29 CFR part 1926, subpart E

“Personal Protective and Life Saving Equipment,”

means the following standards:

(a) Construction Safety and Health Standard Part 6.

“Personal Protective Equipment.”

(b) Occupational Health Standard Part 680.

“Occupational Noise Exposure.”

(c) General Industry and Construction Safety and

Health Standard Part 451. “Respiratory Protection.”

(7) The adopted federal regulations have the same

force and effect as a rule promulgated under the

Michigan occupational safety and health act, 1974 PA

154, MCL 408.1001 to 408.1094.

(8) The American National Standard Institute ANSI

Standard Z 41 “Personal Protection - Protective

Footwear,” 1991 edition, is adopted by reference in

these rules. This standard is available at the Document

Center, Inc., Customer Service, 121 Industrial Road,

Suite 8, Belmont, California 94002, USA, telephone:

(650) 591 7600 or via the internet at the company's

website, www.document center.com, at a cost as of the

time of adoption of these rules of $49.95.

(9) The OSHA regulations adopted in these rules are

available from the United States Department of Labor,

Occupational Safety and Health Administration website,

www.osha.gov, at no charge, as of the time of adoption

of these rules.

(10) The standards adopted in these rules are

available for inspection at the Department of Labor and

Economic Opportunity, MIOSHA, Standards and FOIA

Section, 530 West Allegan Street, P.O. Box 30645,

Lansing, Michigan, 48909-8145.

(11) The standards adopted in these rules may be

obtained from the publisher or the Department of Labor

and Economic Opportunity, MIOSHA, Standards and

FOIA Section, 530 West Allegan Street, P.O. Box

30645, Lansing, Michigan, 48909-8145, at the cost

charged in this rule, plus $20.00 for shipping and

handling.

(12) The following Michigan Occupational Safety and

Health Administration (MIOSHA) standards are

referenced in these rules. Up to 5 copies of these

standards may be obtained at no charge from the

Department of Labor and Economic Opportunity,

MIOSHA, Standards and FOIA Section, 530 West

Allegan Street, P.O. Box 30645, Lansing, Michigan,

48909-8145 or via the internet at the following website:

www.michigan.gov/mioshastandards. For quantities

greater than 5, the cost, as of the time of adoption of

these rules, is 4 cents per page.

(a) Construction Safety Standard Part 45. “Fall

Protection,” R 408.44501 to R 408.44502.

(b) General Industry and Construction Safety and

Health Standard Part 451. “Respiratory Protection,” R

325.60051 to R 325.60052.

(c) Occupational Health Standard Part 680.

“Occupational Noise Exposure,” R 325.60131.

R 408.40614 Definitions, C to F.

Rule 614. (1) "Contaminant" means any material

which by reason of its action upon, within, or to a person

is likely to cause physical harm.

(2) “Footwear” means wearing apparel for the

feet, such as shoes, boots, slippers, or overshoes,

excluding hosiery.

R 408.40615 Definitions, H to R.

Rule 615. Rule 615. (1) “Helmet,” also called a hard

hat or cap, means a device that is worn on the head and

that is designed to provide limited protection against

impact, flying particles, or electric shock.

(2) “Lanyard” means a rope, suitable for supporting 1

person. One end is fastened to a safety belt or harness

and the other end is secured to a substantial object or a

safety line.

(3) “Lifeline” means a rope, suitable for supporting 1

person, to which a lanyard or safety belt (or harness) is

attached.

(4) “Manufacturer” means a business entity that marks

or directs the permanent marking of the components or

complete devices as compliant with this standard and

sells them as compliant.

(5) “Metatarsal guards” mean guards that are designed

to protect the top of the foot from the toes to the ankle

over the instep of the foot. These guards may be

attached to the outside of shoes.

(6) “O.D.” means optical density and refers to the light

refractive characteristics of a lens.

3

(7) “Protective footwear” means footwear that is

designed, constructed, and classified to protect the

wearer from a potential hazard or hazards.

(8) "Radiant energy" means energy that travels outward

in all directions from its sources.

R 408.40616 Definitions, S, T.

Rule 616. Rule 616. (1) “Safety belt” means a device,

usually worn around the waist which, by reason of its

attachment to a lanyard and lifeline or a structure, will

prevent a worker from falling.

(2) “Safety line” means a device used for emergency

rescue work.

(3) “Sanitizing” means an act or process of destroying

organisms that may cause disease.

(4) “Shell” means the portion of welding helmet or

handshield that covers the wearer’s face and is the part

of a helmet which includes the outermost surface.

(5) “Toe guards” means the guards that fit over the toes

of regular shoes to protect the toes from impact and

compression hazards. These guards may be attached

to the outside of shoes.

R 408.40617 Employer’s and employee’s

responsibilities.

Rule 617. (1) An employer shall not permit defective

or damaged personal protective equipment to be used.

(2) An employer shall require each employee to

wear personal protective equipment as prescribed by

the manufacturer when required by any Michigan

occupational safety and health act (MIOSHA) rule.

(3) If personal protective equipment is required

and is worn in direct contact with the skin, the equipment

shall be sanitized before being reissued to another

employee.

(4) An employer shall require the wearing of

appropriate personal protective equipment in all

operations where there is an exposure to hazardous

conditions or where this part indicates the need for using

such equipment to reduce the hazards to the

employees.

(5) All personal protective equipment shall be of

safe design and constructed for the work to be

performed.

PAYMENT FOR PERSONAL PROTECTIVE

EQUIPMENT

R 408.40617a Payment for personal protective

equipment (PPE).

Rule 617a. Rule 617a. (1) An employer shall provide

at no cost to employees the personal protective

equipment necessary to protect against hazards that the

employer is aware of as a result of any required

assessments.

(2) An employer shall pay for replacement PPE, as

necessary, under either of the following conditions:

(a) When the PPE no longer provides the protection it

was designed to provide.

(b) When the previously provided PPE is no longer

adequate or functional.

(3) When an employee has lost or intentionally damaged

the PPE issued to him or her, an employer is not

required to pay for its replacement and may require the

employee to pay for its replacement.

(4) An employer is not required to pay for prescription

safety eyewear with removable or permanent

sideshields as long as the employer provides safety

eyewear that fits over an employee’s prescription

lenses.

(5) An employer is not required to pay for non-specialty

prescription safety eyewear, provided that the employer

permits these items to be worn off the job-site.

(6) An employer is not required to pay for non-specialty

safety-toe protective footwear, including steel-toe shoes

or steel-toe boots, provided that the employer permits

these items to be worn off the job-site.

(7) When the employer provides metatarsal guards and

allows the employee, at his or her request, to use shoes

or boots with built in metatarsal protection, the employer

is not required to reimburse the employee for the shoes

or boots.

(8) An employer is not required to pay for either of the

following:

(a) Everyday clothing, which includes any of the

following:

(i) Long-sleeve shirts.

(ii) Long pants.

(iii) Street shoes.

(iv) Normal work boots.

(v) Ordinary clothing.

(vi) Skin creams.

(b) Other items used solely for protection from weather,

which includes any of the following:

(i) Winter coats.

(ii) Jackets.

(iii) Gloves.

(iv) Parkas.

(v) Rubber boots.

(vi) Hats.

(vii) Raincoats.

(viii) Ordinary sunglasses.

(ix) Sunscreen.

(9) An employer shall pay for protection when ordinary

weather gear is not sufficient to protect an employee

and special equipment or extraordinary clothing is

needed to protect the employee from unusually severe

weather conditions. Clothing used in artificially

controlled environments with extreme hot or cold

temperatures, such as freezers, is not considered part

of the weather gear exception.

(10) All of the following apply to upgraded and

personalized PPE:

(a) An employer is not required to pay for PPE

requested by an employee that exceeds the PPE

requirements, provided that the employer provides PPE

that meets the standards at no cost to the employee.

(b) If an employer allows an employee to acquire and

use upgraded or personalized PPE, then the employer

is not required to reimburse the employee for the

equipment, provided that the employer has provided

adequate PPE at no cost to the employee.

4

(c) An employer shall evaluate an employee’s upgraded

or personalized PPE to ensure that it is in compliance

with all of the following:

(i) Adequate to protect from hazards present in the

workplace.

(ii) Properly maintained.

(iii) Kept in a sanitary condition.

(11) When the provisions of another MIOSHA standard

specify whether the employer shall pay for specific

equipment, the payment provisions of that standard

prevails.

R 408.40624a Rescinded.

FOOT AND TOE PROTECTION

R 408.40625 Foot and toe protection.

Rule 625. (1) Safety toe footwear shall bear a

permanent mark to show the manufacturer’s name or

trademark and to show certification of compliance with

ANSI standard Z-41 “Personal Protection - Protective

Footwear,” 1991 edition, as adopted in R 408.40601(8).

(2) An employer shall ensure that each affected

employee wears foot protection or toe protection, or

both, if conditions of the job are likely to cause a foot

injury.

(3) If a hazard is created from a process,

chemical, or mechanical irritant which could cause an

injury or impairment to the feet by absorption or physical

contact, other than from impact, then the employer shall

provide any of the following to the employee:

(a) Boots.

(b) Overshoes.

(c) Rubbers.

(d) Wooden-soled shoes.

(e) The equivalent to subdivisions (a) to (d) of this

subrule.

HAND AND BODY PROTECTION

R 408.40626 Hand and body protection.

Rule 626. (1) An employee who handles rough,

sharp-edged, abrasive materials, or whose work

subjects the hands to any of the following, shall wear

hand protection of a type suitable for the work being

performed:

(a) Lacerations.

(b) Punctures.

(c) Burns.

(d) Bruises.

(2) Cloth gloves shall not be worn when operating

rotating equipment such as a drill or a powered

threading machine.

(3) Precautions shall be taken with regard to

synthetic clothing that is worn near a source of flame,

spark, a hot surface, or material that could ignite the

clothing.

(4) An employee shall not wear loose clothing,

neckwear encircling the neck, or exposed jewelry, such

as rings and necklaces, near a machine having

reciprocating or rotating shafts or spindles or when

handling material that could catch on clothing or jewelry

and cause injury. A ring shall not be worn on the finger

unless covered by a glove or tape.

(5) When an employee is exposed to hazards

such as radiation, alkalies, acids, abrasives, and

temperature extremes other than those caused by

weather conditions, appropriate head, body, and hand

protection shall be worn to protect the employee from

that hazard. Such personal protective equipment shall

be provided by the employer.

FALL PROTECTION

R 408.40631 Fall protection.

Rule 631. An employer shall ensure that each

employee whose fall protection is not covered by

another MIOSHA safety standard, and the employee’s

work area is more than 6 feet above the ground, floor,

water, or other surface, shall be protected as prescribed

in Construction Safety Standard Part 45 “Fall

Protection.” The following systems are included in

Construction Safety Standard Part 45 “Fall Protection:”

(a) Guardrail systems.

(b) Safety net systems.

(c) Personal fall arrest systems.

R 408.40636 Working over or near water.

Rule 636. (1) Where a possibility of drowning exists,

each employee working over or adjacent to water shall

wear a life jacket or buoyant work vest. The life jacket or

buoyant vest shall bear a label, “U.S. Coast Guard

approved.”

(2) Before and after each use, a competent person shall

inspect the life jacket or buoyant vest for defects which

might alter its strength or buoyancy. Defective units shall

not be used.

(3) A ring buoy with not less than 90 feet of safety line

shall be provided and shall be readily available for

rescue operations. The distance between the buoys

shall not be more than 200 feet.

(4) Not less than 1 lifesaving boat equipped with a

method of propulsion that is effective for the water

conditions shall be available at the location where an

employee works over or adjacent to water.

5

1926.28 - PERSONAL PROTECTIVE EQUIPMENT

1926.28(a) The employer is responsible for requiring the wearing of appropriate personal protective equipment in all

operations where there is an exposure to hazardous conditions or where this part indicates the need for using such

equipment to reduce the hazards to the employees.

1926.28(b) Regulations governing the use, selection, and maintenance of personal protective and lifesaving

equipment are described under Subpart E of this part.

6

1926.97 – Electrical Protective Equipment

1926.97(a) Design requirements for specific types of electrical protective equipment. Rubber insulating

blankets, rubber insulating matting, rubber insulating covers, rubber insulating line hose, rubber insulating gloves,

and rubber insulating sleeves shall meet the following requirements:

1926.97(a)(1) Manufacture and marking of rubber insulating equipment.

1926.97(a)(1)(i) Blankets, gloves, and sleeves shall be produced by a seamless process.

1926.97(a)(1)(ii) Each item shall be clearly marked as follows:

1926.97(a)(1)(ii)(A) Class 00 equipment shall be marked Class 00.

1926.97(a)(1)(ii)(B) Class 0 equipment shall be marked Class 0.

1926.97(a)(1)(ii)(C) Class 1 equipment shall be marked Class 1.

1926.97(a)(1)(ii)(D) Class 2 equipment shall be marked Class 2.

1926.97(a)(1)(ii)(E) Class 3 equipment shall be marked Class 3.

1926.97(a)(1)(ii)(F) Class 4 equipment shall be marked Class 4.

1926.97(a)(1)(ii)(G) Nonozone-resistant equipment shall be marked Type I.

1926.97(a)(1)(ii)(H) Ozone-resistant equipment shall be marked Type II.

1926.97(a)(1)(ii)(I) Other relevant markings, such as the manufacturer's identification and the size of the equipment,

may also be provided.

1926.97(a)(1)(iii) Markings shall be nonconducting and shall be applied in such a manner as not to impair the

insulating qualities of the equipment.

1926.97(a)(1)(iv) Markings on gloves shall be confined to the cuff portion of the glove.

1926.97(a)(2) Electrical requirements.

1926.97(a)(2)(i) Equipment shall be capable of withstanding the ac proof-test voltage specified in Table E-1 or the

dc proof-test voltage specified in Table E-2.

1926.97(a)(2)(i)(A) The proof test shall reliably indicate that the equipment can withstand the voltage involved.

1926.97(a)(2)(i)(B) The test voltage shall be applied continuously for 3 minutes for equipment other than matting and

shall be applied continuously for 1 minute for matting.

1926.97(a)(2)(i)(C) Gloves shall also be capable of separately withstanding the ac proof-test voltage specified in

Table E-1 after a 16-hour water soak. (See the note following paragraph (a)(3)(ii)(B) of this section.)

1926.97(a)(2)(ii) When the ac proof test is used on gloves, the 60-hertz proof-test current may not exceed the

values specified in Table E-1 at any time during the test period.

1926.97(a)(2)(ii)(A) If the ac proof test is made at a frequency other than 60 hertz, the permissible proof-test current

shall be computed from the direct ratio of the frequencies.

1926.97(a)(2)(ii)(B) For the test, gloves (right side out) shall be filled with tap water and immersed in water to a depth

that is in accordance with Table E-3. Water shall be added to or removed from the glove, as necessary, so that the

water level is the same inside and outside the glove.

1926.97(a)(2)(ii)(C) After the 16-hour water soak specified in paragraph (a)(2)(i)(C) of this section, the 60-hertz proof-

test current may not exceed the values given in Table E-1 by more than 2 milliamperes.

1926.97(a)(2)(iii) Equipment that has been subjected to a minimum breakdown voltage test may not be used for

electrical protection. (See the note following paragraph (a)(3)(ii)(B) of this section.)

1926.97(a)(2)(iv) Material used for Type II insulating equipment shall be capable of withstanding an ozone test, with

no visible effects. The ozone test shall reliably indicate that the material will resist ozone exposure in actual use. Any

visible signs of ozone deterioration of the material, such as checking, cracking, breaks, or pitting, is evidence of failure

to meet the requirements for ozone resistant material. (See the note following paragraph (a)(3)(ii)(B) of this section.)

1926.97(a)(3) Workmanship and finish.

1926.97(a)(3)(i) Equipment shall be free of physical irregularities that can adversely affect the insulating properties

of the equipment and that can be detected by the tests or inspections required under this section.

1926.97(a)(3)(ii) Surface irregularities that may be present on all rubber goods (because of imperfections on forms

or molds or because of inherent difficulties in the manufacturing process) and that may appear as indentations,

protuberances, or imbedded foreign material are acceptable under the following conditions:

1926.97(a)(3)(ii)(A) The indentation or protuberance blends into a smooth slope when the material is stretched.

1926.97(a)(3)(ii)(B) Foreign material remains in place when the insulating material is folded and stretches with the

insulating material surrounding it.

Note to paragraph (a): Rubber insulating equipment meeting the following national consensus standards is

deemed to be in compliance with the performance requirements of paragraph (a) of this section:

American Society for Testing and Materials (ASTM) D120-09, Standard Specification for Rubber Insulating Gloves.

ASTM D178-01 (2010), Standard Specification for Rubber Insulating Matting.

7

ASTM D1048-12, Standard Specification for Rubber Insulating Blankets.

ASTM D1049-98 (2010), Standard Specification for Rubber Insulating Covers.

ASTM D1050-05 (2011), Standard Specification for Rubber Insulating Line Hose.

ASTM D1051-08, Standard Specification for Rubber Insulating Sleeves.

The preceding standards also contain specifications for conducting the various tests required in paragraph (a) of

this section. For example, the ac and dc proof tests, the breakdown test, the water-soak procedure, and the ozone

test mentioned in this paragraph are described in detail in these ASTM standards.

ASTM F1236-96 (2012), Standard Guide for Visual Inspection of Electrical Protective Rubber Products, presents

methods and techniques for the visual inspection of electrical protective equipment made of rubber. This guide also

contains descriptions and photographs of irregularities that can be found in this equipment.

ASTM F819-10, Standard Terminology Relating to Electrical Protective Equipment for Workers, includes definitions

of terms relating to the electrical protective equipment covered under this section.

1926.97(b) Design requirements for other types of electrical protective equipment. The following

requirements apply to the design and manufacture of electrical protective equipment that is not covered by

paragraph (a) of this section:

1926.97(b)(1) Voltage withstand. Insulating equipment used for the protection of employees shall be capable of

withstanding, without failure, the voltages that may be imposed upon it.

Note to paragraph (b)(1):

These voltages include transient overvoltages, such as switching surges, as well as nominal line voltage. See

appendix B to subpart V of this part for a discussion of transient overvoltages on electric power transmission and

distribution systems. See IEEE Std 516-2009, IEEE Guide for Maintenance Methods on Energized Power Lines, for

methods of determining the magnitude of transient overvoltages on an electrical system and for a discussion

comparing the ability of insulation equipment to withstand a transient overvoltage based on its ability to withstand

ac voltage testing.

1926.97(b)(2) Equipment current.

1926.97(b)(2)(i) Protective equipment used for the primary insulation of employees from energized circuit parts

shall be capable of passing a current test when subjected to the highest nominal voltage on which the equipment is

to be used.

1926.97(b)(2)(ii) When insulating equipment is tested in accordance with paragraph (b)(2)(i) of this section, the

equipment current may not exceed 1 microampere per kilovolt of phase-to-phase applied voltage.

Note 1 to paragraph (b)(2):

This paragraph applies to equipment that provides primary insulation of employees from energized parts. It does

not apply to equipment used for secondary insulation or equipment used for brush contact only.

Note 2 to paragraph (b)(2):

For ac excitation, this current consists of three components: Capacitive current because of the dielectric properties

of the insulating material itself, conduction current through the volume of the insulating equipment, and leakage

current along the surface of the tool or equipment. The conduction current is normally negligible. For clean, dry

insulating equipment, the leakage current is small, and the capacitive current predominates.

Note to paragraph (b):

Plastic guard equipment is deemed to conform to the performance requirements of paragraph (b) of this section if it

meets, and is used in accordance with, ASTM F712-06 (2011), Standard Test Methods and Specifications for

Electrically Insulating Plastic Guard Equipment for Protection of Workers.

1926.97(c) In-service care and use of electrical protective equipment.

1926.97(c)(1) General. Electrical protective equipment shall be maintained in a safe, reliable condition.

8

1926.97(c)(2) Specific requirements. The following specific requirements apply to rubber insulating blankets,

rubber insulating covers, rubber insulating line hose, rubber insulating gloves, and rubber insulating sleeves:

1926.97(c)(2)(i) Maximum use voltages shall conform to those listed in Table E-4.

1926.97(c)(2)(ii) Insulating equipment shall be inspected for damage before each day's use and immediately

following any incident that can reasonably be suspected of causing damage. Insulating gloves shall be given an air

test, along with the inspection.

Note to paragraph (c)(2)(ii): ASTM F1236-96 (2012), Standard Guide for Visual Inspection of Electrical Protective

Rubber Products, presents methods and techniques for the visual inspection of electrical protective equipment

made of rubber. This guide also contains descriptions and photographs of irregularities that can be found in this

equipment.

1926.97(c)(2)(iii) Insulating equipment with any of the following defects may not be used:

1926.97(c)(2)(iii)(A) A hole, tear, puncture, or cut;

1926.97(c)(2)(iii)(B) Ozone cutting or ozone checking (that is, a series of interlacing cracks produced by ozone on

rubber under mechanical stress);

1926.97(c)(2)(iii)(C) An embedded foreign object;

1926.97(c)(2)(iii)(D) Any of the following texture changes: Swelling, softening, hardening, or becoming sticky or

inelastic.

1926.97(c)(2)(iii)(E) Any other defect that damages the insulating properties.

1926.97(c)(2)(iv) Insulating equipment found to have other defects that might affect its insulating properties shall be

removed from service and returned for testing under paragraphs (c)(2)(viii) and (c)(2)(ix) of this section.

1926.97(c)(2)(v) Insulating equipment shall be cleaned as needed to remove foreign substances.

1926.97(c)(2)(vi) Insulating equipment shall be stored in such a location and in such a manner as to protect it from

light, temperature extremes, excessive humidity, ozone, and other damaging substances and conditions.

1926.97(c)(2)(vii) Protector gloves shall be worn over insulating gloves, except as follows:

1926.97(c)(2)(vii)(A) Protector gloves need not be used with Class 0 gloves, under limited-use conditions, when

small equipment and parts manipulation necessitate unusually high finger dexterity.

Note to paragraph (c)(2)(vii)(A): Persons inspecting rubber insulating gloves used under these conditions need to

take extra care in visually examining them. Employees using rubber insulating gloves under these conditions need

to take extra care to avoid handling sharp objects.

1926.97(c)(2)(vii)(B)

If the voltage does not exceed 250 volts, ac, or 375 volts, dc, protector gloves need not be used with Class 00

gloves, under limited-use conditions, when small equipment and parts manipulation necessitate unusually high

finger dexterity.

Note to paragraph (c)(2)(vii)(B): Persons inspecting rubber insulating gloves used under these conditions need to

take extra care in visually examining them. Employees using rubber insulating gloves under these conditions need

to take extra care to avoid handling sharp objects.

1926.97(c)(2)(vii)(C) Any other class of glove may be used without protector gloves, under limited-use conditions,

when small equipment and parts manipulation necessitate unusually high finger dexterity but only if the employer

can demonstrate that the possibility of physical damage to the gloves is small and if the class of glove is one class

higher than that required for the voltage involved.

1926.97(c)(2)(vii)(D) Insulating gloves that have been used without protector gloves may not be reused until they

have been tested under the provisions of paragraphs (c)(2)(viii) and (c)(2)(ix) of this section.

1926.97(c)(2)(viii) Electrical protective equipment shall be subjected to periodic electrical tests. Test voltages and

the maximum intervals between tests shall be in accordance with Table E-4 and Table E-5.

1926.97(c)(2)(ix) The test method used under paragraphs (c)(2)(viii) and (c)(2)(xi) of this section shall reliably

indicate whether the insulating equipment can withstand the voltages involved.

Note to paragraph (c)(2)(ix): Standard electrical test methods considered as meeting this paragraph are given in

the following national consensus standards:

ASTM D120-09, Standard Specification for Rubber Insulating Gloves.

ASTM D178-01 (2010), Standard Specification for Rubber Insulating Matting.

ASTM D1048-12, Standard Specification for Rubber Insulating Blankets.

9

ASTM D1049-98 (2010), Standard Specification for Rubber Insulating Covers.

ASTM D1050-05 (2011), Standard Specification for Rubber Insulating Line Hose.

ASTM D1051-08, Standard Specification for Rubber Insulating Sleeves.

ASTM F478-09, Standard Specification for In-Service Care of Insulating Line Hose and Covers.

ASTM F479-06 (2011), Standard Specification for In-Service Care of Insulating Blankets.

ASTM F496-08, Standard Specification for In-Service Care of Insulating Gloves and Sleeves.

1926.97(c)(2)(x) Insulating equipment failing to pass inspections or electrical tests may not be used by employees,

except as follows:

1926.97(c)(2)(x)(A) Rubber insulating line hose may be used in shorter lengths with the defective portion cut off.

1926.97(c)(2)(x)(B) Rubber insulating blankets may be salvaged by severing the defective area from the

undamaged portion of the blanket. The resulting undamaged area may not be smaller than 560 millimeters by 560

millimeters (22 inches by 22 inches) for Class 1, 2, 3, and 4 blankets.

1926.97(c)(2)(x)(C) Rubber insulating blankets may be repaired using a compatible patch that results in physical

and electrical properties equal to those of the blanket.

1926.97(c)(2)(x)(D) Rubber insulating gloves and sleeves with minor physical defects, such as small cuts, tears, or

punctures, may be repaired by the application of a compatible patch. Also, rubber insulating gloves and sleeves

with minor surface blemishes may be repaired with a compatible liquid compound. The repaired area shall have

electrical and physical properties equal to those of the surrounding material. Repairs to gloves are permitted only in

the area between the wrist and the reinforced edge of the opening.

1926.97(c)(2)(xi) Repaired insulating equipment shall be retested before it may be used by employees.

1926.97(c)(2)(xii) The employer shall certify that equipment has been tested in accordance with the requirements

of paragraphs (c)(2)(iv), (c)(2)(vii)(D), (c)(2)(viii), (c)(2)(ix), and (c)(2)(xi) of this section. The certification shall

identify the equipment that passed the test and the date it was tested and shall be made available upon request to

the Assistant Secretary for Occupational Safety and Health and to employees or their authorized representatives.

Note to paragraph (c)(2)(xii): Marking equipment with, and entering onto logs, the results of the tests and the

dates of testing are two acceptable means of meeting the certification requirement.

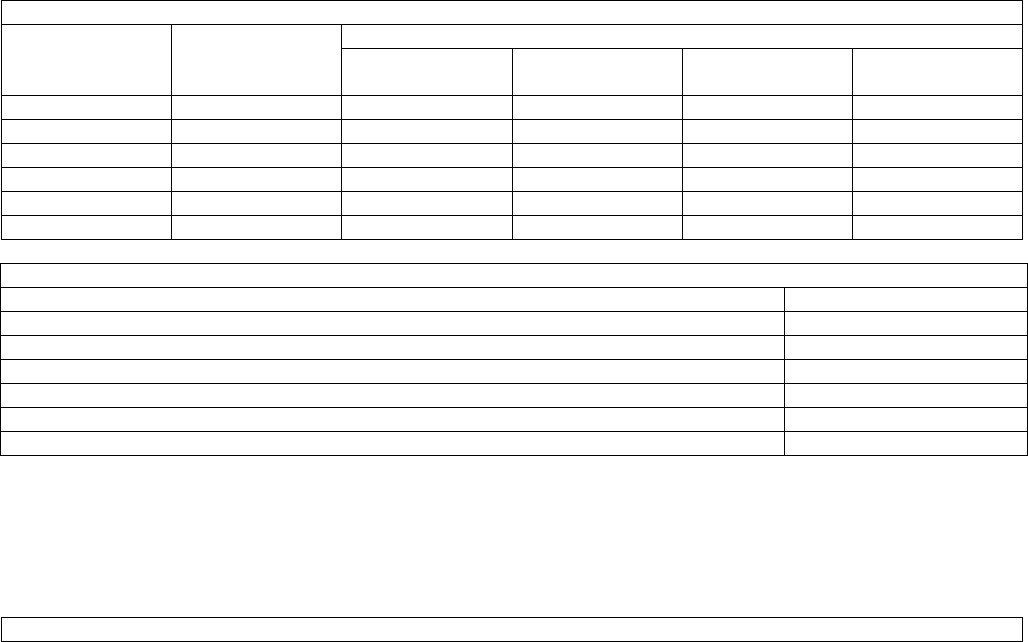

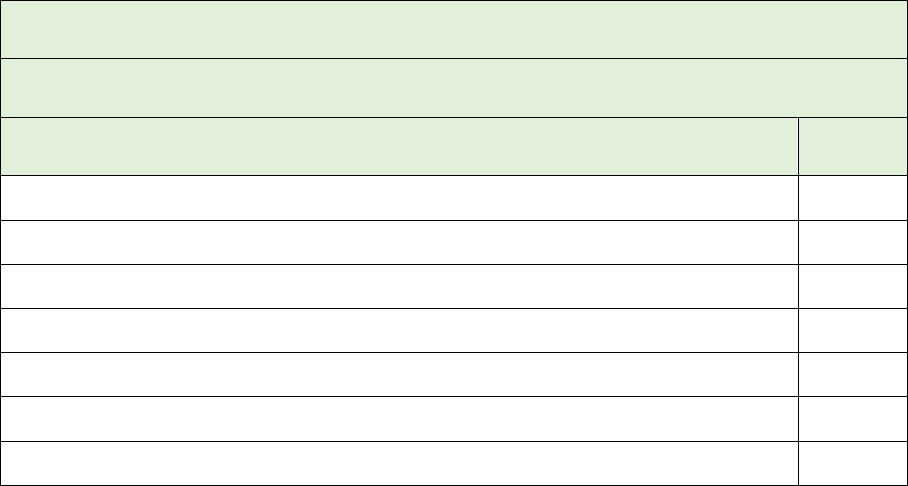

TABLE E-1-AC PROOF-TEST REQUIREMENTS

Class of

equipment

Proof-test

voltage rms V

Maximum proof-test current, mA (gloves only)

280-mm (11-in)

glove

360-mm (14-in)

glove

410-mm (16-in)

glove

460-mm (18-in)

glove

00

2,500

8

12

……………

……………..

0

5,000

8

12

14

16

1

10,000

…………….

14

16

18

2

20,000

…………….

16

18

20

3

30,000

…………….

18

20

22

4

40,000

…………….

……………

22

24

TABLE E-2-DC PROOF-TEST REQUIRMENTS

Class of equipment

Proof-test voltage

00……………………………………………………………………………………………

10,000

0……………………………………………………………………………………………..

20,000

1……………………………………………………………………………………………..

40,000

2……………………………………………………………………………………………..

50,000

3……………………………………………………………………………………………..

60,000

4……………………………………………………………………………………………..

70,000

Note: The dc voltages listed in this table are not appropriate for proof testing rubber insulating line hose or covers.

For this equipment, dc proof tests shall use a voltage high enough to indicate that the equipment can be safely

used at the voltages listed in Table E-4. See ASTM D1050-05 (2011) and ASTM D1049-98 (2010) for further

information on proof tests for rubber insulating line hose and covers, respectively.

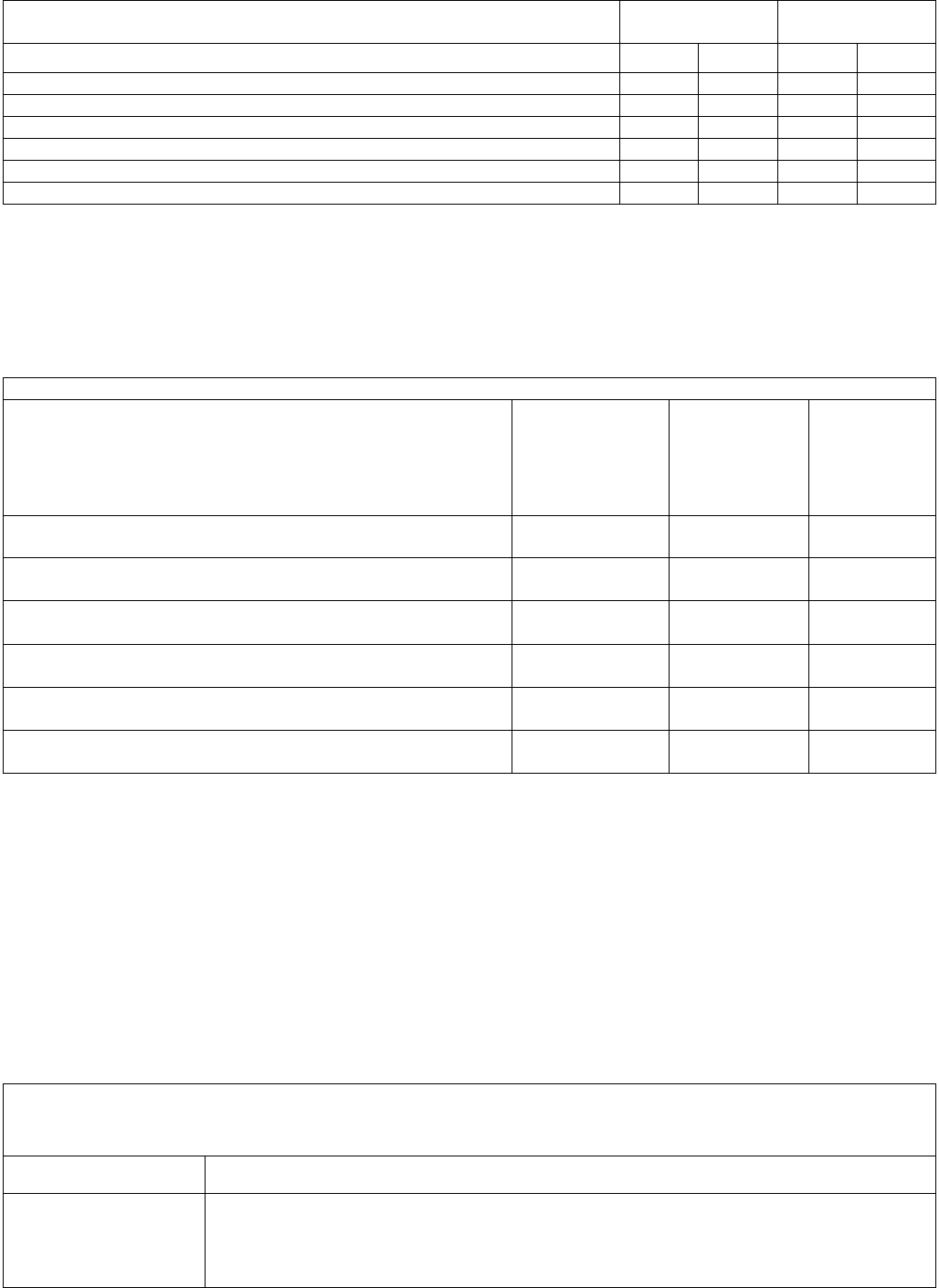

TABLE E-3-GLOVE TESTS-WATER LEVEL 1, 2

10

Class of glove

AC proof test

DC proof test

mm

in

mm

in

00……………………………………………………………………..

38

1.5

38

1.5

0……………………………………………………………………….

38

1.5

38

1.5

1……………………………………………………………………….

38

1.5

51

2.0

2……………………………………………………………………….

64

2.5

76

3.0

3……………………………………………………………………….

89

3.5

102

4.0

4……………………………………………………………………….

127

5.0

153

6.0

1

The water level is given as the clearance from the reinforced edge of the glove to the water line, with a

tolerance of ±13 mm. (±0.5 in.).

2

If atmospheric conditions make the specified clearances impractical, the clearances may be increased by a

maximum of 25 mm. (1 in.).

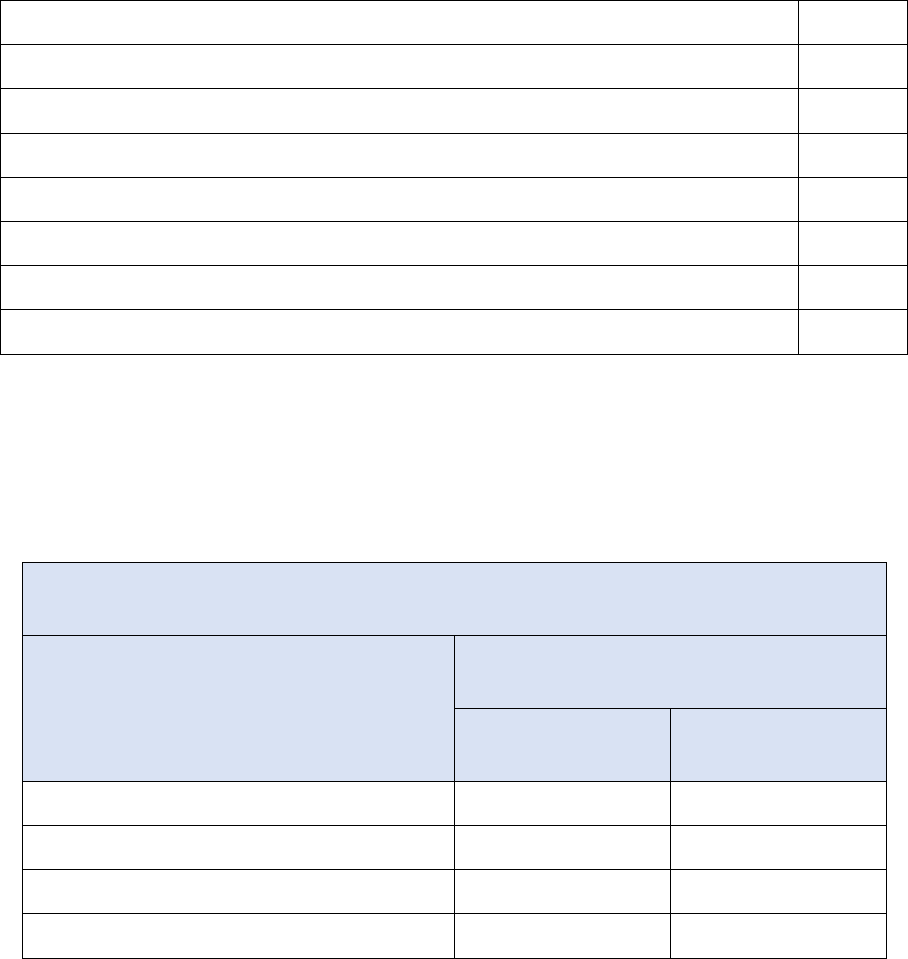

TABLE E-4-RUBBER INSULATING EQUIPMENT, VOLTAGE REQUIREMENTS

Class of equipment

Maximum use

voltage

1

AC

Retest

voltage

2

AC

rms

Retest

voltage

2

DC

avg

00

……………………………………………………………

500

2,500

10,000

0

……………………………………………………………

1,000

5,000

20,000

1

…………………………………………………………….

7,500

10,000

40,000

2

…………………………………………………………….

17,000

20,000

50,000

3

……………………………………………………………..

26,500

30,000

60,000

4

……………………………………………………………..

36,000

40,000

70,000

1

The maximum use voltage is the ac voltage (rms) classification of the protective equipment that designates

the maximum nominal design voltage of the energized system that may be safely worked. The nominal design

voltage is equal to the phase-to-phase voltage on multiphase circuits. However, the phase-to-ground potential

is considered to be the nominal design voltage if:

(1) There is no multiphase exposure in a system area and the voltage exposure is limited to the phase-to-

ground potential, or

(2) The electric equipment and devices are insulated or isolated or both so that the multiphase exposure on a

grounded wye circuit is removed.

2

The proof-test voltage shall be applied continuously for at least 1 minute, but no more than 3 minutes.

TABLE E-5-RUBBER INSULATING EQUIPMENT, TEST INTERVALS

Type of equipment

When to test

Rubber insulating

line hose

………………..

Upon indication that insulating value is suspect and after repair.

11

Rubber insulating

covers

………………..

Upon indication that insulating value is suspect and after repair.

Rubber insulating

blankets

………………..

Before first issue and every 12 months thereafter;

1

upon indication that insulating

value is suspect; and after repair.

Rubber insulating

gloves

………………..

Before first issue and every 6 months thereafter;

1

upon indication that insulating

value is suspect; after repair; and after use without protectors.

Rubber insulating

sleeves

………………..

Before first issue and every 12 months thereafter;

1

upon indication that insulating

value is suspect; and after repair.

1

If the insulating equipment has been electrically tested but not issued for service, the insulating equipment

may not be placed into service unless it has been electrically tested within the previous 12 months.

[58 FR 35152, June 30, 1993; 61 FR 31427, June 20, 1996; 79 FR 20693-20696, July 10, 2014]

12

1926.100 - HEAD PROTECTION

1926.100(a) Employees working in areas where there is a possible danger of head injury from impact, or from falling

or flying objects, or from electrical shock and burns, shall be protected by protective helmets.

1926.100(b) Criteria for head protection.

1926.100(b)(1) The employer must provide each employee with head protection that meets the specifications

contained in any of the following consensus standards:

1926.100(b)(1)(i) American National Standards Institute (ANSI) Z89.1-2009, "American National Standard for

Industrial Head Protection," incorporated by reference in 1926.6;

1926.100(b)(1)(ii) American National Standards Institute (ANSI) Z89.1-2003, "American National Standard for

Industrial Head Protection," incorporated by reference in 1926.6; or

1926.100(b)(1)(iii) American National Standards Institute (ANSI) Z89.1-1997, "American National Standard for

Personnel Protection-Protective Headwear for Industrial Workers-Requirements," incorporated by reference in

1926.6.

1926.100(b)(2) The employer must ensure that the head protection provided for each employee exposed to high-

voltage electric shock and burns also meets the specifications contained in Section 9.7 ("Electrical Insulation") of

any of the consensus standards identified in paragraph (b)(1) of this section.

1926.100(b)(3) OSHA will deem any head protection device that the employer demonstrates is at least as effective

as a head protection device constructed in accordance with one of the consensus standards identified in paragraph

(b)(1) of this section to be in compliance with the requirements of this section.

[77 FR 37600, June 22, 2012; 77 FR 42988, July 23, 2012]

13

1926.102 - EYE AND FACE PROTECTION

1926.102(a) General requirements.

1926.102(a)(1) The employer shall ensure that each affected employee uses appropriate eye or face protection when

exposed to eye or face hazards from flying particles, molten metal, liquid chemicals, acids or caustic liquids, chemical

gases or vapors, or potentially injurious light radiation.

1926.102(a)(2) The employer shall ensure that each affected employee uses eye protection that provides side

protection when there is a hazard from flying objects. Detachable side protectors (e.g. clip-on or slide-on side shields)

meeting the pertinent requirements of this section are acceptable.

1926.102(a)(3) The employer shall ensure that each affected employee who wears prescription lenses while engaged

in operations that involve eye hazards wears eye protection that incorporates the prescription in its design, or wears

eye protection that can be worn over the prescription lenses without disturbing the proper position of the prescription

lenses or the protective lenses.

1926.102(a)(4) Eye and face PPE shall be distinctly marked to facilitate identification of the manufacturer.

1926.102(a)(5) Protectors shall meet the following minimum requirements:

1926.102(a)(5)(i) They shall provide adequate protection against the particular hazards for which they are designed.

1926.102(a)(5)(ii) They shall be reasonably comfortable when worn under the designated conditions.

1926.102(a)(5)(iii) They shall fit snugly and shall not unduly interfere with the movements of the wearer.

1926.102(a)(5)(iv) They shall be durable.

1926.102(a)(5)(v) They shall be capable of being disinfected.

1926.102(a)(5)(vi) They shall be easily cleanable.

1926.102(b) Criteria for protective eye and face protection.

1926.102(b)(1) Protective eye and face protection devices must comply with any of the following consensus

standards:

1926.102(b)(1)(i) ANSI/ISEA Z87.1-2010, Occupational and Educational Personal Eye and Face Protection Devices,

incorporated by reference in 1926.6;

1926.102(b)(1)(ii) ANSI Z87.1-2003, Occupational and Educational Personal Eye and Face Protection Devices,

incorporated by reference in 1926.6; or

1926.102(b)(1)(iii) ANSI Z87.1-1989 (R-1998), Practice for Occupational and Educational Eye and Face Protection,

incorporated by reference in 1926.6;

1926.102(b)(2) Protective eye and face protection devices that the employer demonstrates are at least as effective

as protective eye and face protection devices that are constructed in accordance with one of the above consensus

standards will be deemed to be in compliance with the requirements of this section.

1926.102(c) Protection against radiant energy

1926.102(c)(1) Selection of shade numbers for welding filter. Table E-1 shall be used as a guide for the selection of

the proper shade numbers of filter lenses or plates used in welding. Shades more dense than those listed may be

used to suit the individual's needs.

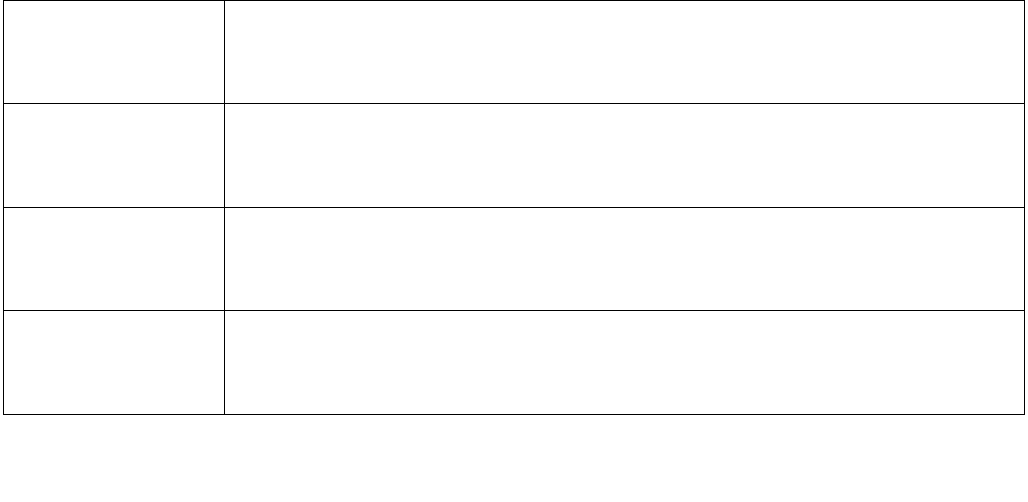

TABLE E-1

FILTER LENS SHADE NUMBERS FOR PROTECTION AGAINST RADIANT ENERGY

WELDING OPERATION

SHADE

NUMBER

Shielded metal-arc welding 1/16-, 3/32-, 1/8-, 5/32-, inch diameter electrodes

10

Gas-shielded arc welding (nonferrous) 1/16-, 3/32-, 1/8-, 5/32-inch diameter electrodes

11

Gas-shielded arc welding (ferrous) 1/16, 3/32-, 1/8-, 5/32-inch diameter electrodes

12

Shielded metal-arc welding 3/16-, 7/32-, 1/4-inch diameter electrodes

12

5/16-, 3/8-inch diameter electrodes

14

Atomic hydrogen welding

10 - 14

Carbon-arc welding

14

14

Soldering

2

Torch brazing

3 or 4

Light cutting, up to 1 inch

3 or 4

Medium cutting, 1 inch to 6 inches

4 or 5

Heavy cutting, over 6 inches

5 or 6

Gas welding (light), up to 1/8-inch

4 or 5

Gas welding (medium), 1/8-inch to 1/2-inch

5 or 6

Gas welding (heavy), over 1/2-inch

6 or 8

1926.102(c)(2) Laser protection.

1926.102(c)(2)(i) Employees whose occupation or assignment requires exposure to laser beams shall be

furnished suitable laser safety goggles which will protect for the specific wavelength of the laser and be of optical

density (O.D.) adequate for the energy involved. Table E-2 lists the maximum power or energy density for which

adequate protection is afforded by glasses of optical densities from 5 through 8. Output levels falling between lines

in this table shall require the higher optical density.

TABLE E-2

SELECTING LASER SAFETY GLASS

INTENSITY, CW MAXIMUM POWER

DENSITY (WATTS/CM

2

)

ATTENUATION

OPTICAL DENSITY

(O.D.)

ATTENUATION

FACTOR

10

−2

5

10

5

10

−1

6

10

6

1.0

7

10

7

10.0

8

10

8

1926.102(c)(2)(ii) All protective goggles shall bear a label identifying the following data:

1926.102(c)(2)(ii)(A) The laser wavelengths for which use is intended;

1926.102(c)(2)(ii)(B) The optical density of those wavelengths;

1926.102(c)(2)(ii)(C) The visible light transmission.

[44 FR 8577, Feb. 9, 1979; 44 FR 20940, Apr. 6, 1979, as amended at 58 FR 35160, June 30, 1993; 81 FR 16092,

Mar. 25, 2016]

15

1926.105 – SAFETY NETS

1926.105(a) Safety nets shall be provided when workplaces are more than 25 feet above the ground or water

surface, or other surfaces where the use of ladders, scaffolds, catch platforms, temporary floors, safety lines, or

safety belts is impractical.

1926.105(b) Where safety net protection is required by this part, operations shall not be undertaken until the net is

in place and has been tested.

1926.105(c)

1926.105(c)(1) Nets shall extend 8 feet beyond the edge of the work surface where employees are exposed and

shall be installed as close under the work surface as practical but in no case more than 25 feet below such work

surface. Nets shall be hung with sufficient clearance to prevent user's contact with the surfaces or structures below.

Such clearances shall be determined by impact load testing.

1926.105(c)(2) It is intended that only one level of nets be required for bridge construction.

1926.105(d) The mesh size of nets shall not exceed 6 inches by 6 inches. All new nets shall meet accepted

performance standards of 17,500 foot-pounds minimum impact resistance as determined and certified by the

manufacturers, and shall bear a label of proof test. Edge ropes shall provide a minimum breaking strength of 5,000

pounds.

1926.105(e) Forged steel safety hooks or shackles shall be used to fasten the net to its supports.

1926.105(f) Connections between net panels shall develop the full strength of the net.

[59 FR 40729, Aug. 9, 1994; 60 FR 5131, Jan. 26, 1995; 60 FR 39243, Aug. 2, 1995]

16

Michigan Occupational Safety and Health Administration

PO Box 30643

Lansing, Michigan 48909-8143

For technical questions of this standard – Ph: 517-284-7680 (CSHD) or 517-284-7720 (CETD)

To order copies of this standard – Ph: 517-284-7740

The Department of Labor and Economic Opportunity will not

discriminate against any individual or group because of race,

sex, religion, age, national origin, color, marital status,

disability, or political beliefs. Auxiliary aids, services and other

reasonable accommodations are available upon request to

individuals with disabilities.