BY ORDER OF THE

SECRETARY OF THE AIR FORCE

AIR FORCE MANUAL

32-7002

4 FEBRUARY 2020

Civil Engineering

ENVIRONMENTAL COMPLIANCE AND

POLLUTION PREVENTION

COMPLIANCE WITH THIS PUBLICATION IS MANDATORY

ACCESSIBILITY: Publications and forms are available for downloading or ordering on the

e-Publishing website at www.e-Publishing.af.mil.

RELEASABILITY: There are no releasability restrictions on this publication.

OPR: AF/A4CA

Supersedes: AFI 32-7040, 4 November

2014; AFI 32-7042, 7

November 2014; AFI 32-

7086, 4 February 2015,

AFMAN 32-7089, 4

November 2016, AF Form

3952

Certified by: SAF/IE

(Mr. John W. Henderson)

Pages: 104

This manual implements Air Force Policy Directive (AFPD) 32-70, Environmental

Considerations in Air Force Programs and Activities, and Air Force Instruction (AFI) 32-7001,

Environmental Management. This Air Force Manual (AFMAN) applies to all civilian employees

and uniformed members of the Regular Air Force (RegAF), Air Force Reserve (AFR), and Air

National Guard (ANG) reserve components; it also applies to the installations supported by the

Air Force Reserve Command (AFRC), the Air National Guard (ANG), Primary Subordinate Units

not located on AF installations; also to Government-Owned, Contractor Operated (GOCO)

facilities, Direct Reporting Units (DRUs), and Air Force Reserve (AFR) units/bases. This AFMAN

applies to all Air Force installations worldwide, but it does not apply directly to contingency (i.e.,

non-enduring) locations outside the U.S, although is a good source for non-directive information.

See AFI 32-7091, Environmental Management Outside the United States, for additional

environmental guidance for overseas installations. The Air National Guard Readiness Center

(ANGRC) and AFRC, may supplement this manual. All supplements must be routed to the Office

of Primary Responsibility (OPR) of this publication for coordination prior to certification and

2 AFMAN32-7002 4 FEBRUARY 2020

approval. Unless otherwise noted, portions of this AFMAN apply to all enduring installations

outside the United States so long as such application is consistent with international agreements

and does not conflict with applicable host nation final governing standards or Department of

Defense (DoD) 4715.05-G, Overseas Environmental Baseline Guidance Document. Refer

recommended changes and questions about this publication to the Office or Primary Responsibility

(OPR) using the AF Form 847, Recommendation for Change of Publication; route AF Form 847

from the field through the appropriate functional chain of command. The authorities to waive

wing/unit level requirements in this publication are identified with a Tier (T-0, T-1, T-2, or T-3)

number following the compliance statement. See AFI 33-360, Publications and Forms

Management, for a description of the authorities associated with the Tier numbers. Submit requests

for waivers through the chain of command to the appropriate Tier waiver approval authority, or

alternately, to the requestors immediate commander for non-tiered compliance items. Ensure all

records created as a result of the processes prescribed in this publication are maintained in

accordance with Air Force Manual 33-363, Management of Records, and disposed of in

accordance with Air Force Records Disposition Schedule located in the Air Force Records

Information Management System. This manual requires the collection and or maintenance of

information protected by Title 5 United States Code (USC) Section (§) 552a, The Privacy Act of

1974 authorized by 42 USC §§ 7401-7671q, Clean Air Act and 42 USC § 7418, Control of

pollution from Federal Facilities. The applicable System of Record Notice Environmental

Protection Agency-GOVT-1, Emissions Inspection and Maintenance Records for Federal

Employees Parking at Federal Parking Facilities, is available at:

http://www.epa.gov/privacy/notice/epa-govt-1.htm, or https://www.epa.gov/privacy/privacy-

act-system-records-emissions-inspection-and-maintenance-records-federal-employees. The

use of the name or mark of any specific manufacturer, commercial product, commodity, or service

in this publication does not imply endorsement by the Air Force (AF).

Chapter 1—INTRODUCTION 6

1.1. Overview. ................................................................................................................ 6

1.2. Scope. ...................................................................................................................... 6

1.3. Statutes and Regulations. ........................................................................................ 6

1.4. Environmental Management System (EMS). ......................................................... 8

Chapter 2—ROLES AND RESPONSIBILITIES 9

2.1. Deputy Assistant Secretary of the Air Force for Environment, Safety, and

Infrastructure (SAF/IEE). ....................................................................................... 9

2.2. The General Counsel of the Department of the Air Force (SAF/GC), through the

Deputy General Counsel for Installations, Energy and Environment (SAF/GCN). 9

2.3. Assistant Secretary of the Air Force for Acquisition, Technology, and Logistics

(SAF/AQ). ............................................................................................................... 10

AFMAN32-7002 4 FEBRUARY 2020 3

2.4. The Headquarters, United States Air Force, Deputy Chief of Staff for Logistics,

Engineering and Force Protection, Directorate of Civil Engineers (AF/A4C). ...... 10

2.5. The Headquarters, United States Air Force, Deputy Chief of Staff for Logistics,

Engineering, & Force Protection, Directorate of Logistics (AF/A4L). .................. 11

2.6. The Headquarters, United States Air Force, Surgeon General (AF/SG). ............... 11

2.7. The Headquarters, United States Air Force, Chief of Safety (AF/SE). .................. 12

2.8. Headquarters, United States Air Force, The Judge Advocate General (AF/JA)

through the Air Force Legal Operations Agency, Civil Law and Litigation

Directorate, Environmental Law and Litigation Division (AFLOA/JACE). .......... 12

2.9. The Chiefs of the National Guard Bureau (NGB) and Air Force Reserve

Command (AFRC). ................................................................................................. 12

2.10. Major Command (MAJCOM) or Air National Guard Readiness Center

(ANGRC) Commander and/or Environment, Safety, and Occupational Health

Council (ESOHC) Chair. ........................................................................................ 13

2.11. Air Force Installation and Mission Support Center (AFIMSC). ............................. 13

2.12. The Air Force Civil Engineer Center, Environmental Directorate (AFCEC/CZ). . 13

2.13. AFCEC Operations, Energy, and Readiness Directorates (AFCEC/CO, CF, CN,

and CX), to the AFIMSC, will provide criteria, standards, procedural guidance,

and technical support for environmental compliance related activities to include

air emission controls, the execution of RCRA Military Munitions Rule (40 CFR

Part 266, Subpart M, Standards for The Management of Specific Hazardous

Wastes and Specific Types of Hazardous Waste Management Facilities: ............. 17

2.14. Installation/Center Commander. ............................................................................. 18

2.15. Base Civil Engineer (BCE) will (RegAF Installations): .......................................... 20

2.16. The Civil Engineer-Installation Management Flight, Environmental Element

(CEIE) or AFR Component (ANG or AFRC) Environmental Management Office

(hereafter referred to as Installation Environmental Element), is the installation

environmental function with overall management and execution responsibility for

the installation’s environmental program and focal point for monitoring the

installation’s compliance status with all applicable federal, state, local, and host-

nation requirements. ................................................................................................ 21

2.17. Installation Staff Judge Advocates (JA), or NGB JA for ANG and MAJCOM/JA

for AFRC, will: ........................................................................................................ 24

2.18. The Air Force Institute of Technology (AFIT) Civil Engineer School will, in

coordination with AFCEC/CZ, provide educational/training programs in support

4 AFMAN32-7002 4 FEBRUARY 2020

of environmental compliance, pollution prevention and hazardous material

management. ........................................................................................................... 24

CHAPTER 3—HAZARDOUS MATERIAL MANAGEMENT 25

3.1. General Requirements - Hazardous Materials Management Process (HMMP). .... 25

3.2. Establishing and Running Installation Hazardous Material Management Process

(HMMP) Teams. ...................................................................................................... 26

3.3. Installation HAZMAT Management Guidance and Procedures. ............................ 27

CHAPTER 4—AIR QUALITY COMPLIANCE AND RESOURCE MANAGEMENT 38

4.1. General Requirements. ............................................................................................ 38

4.2. General Program Guidelines. .................................................................................. 38

4.3. Air Quality Management System. ........................................................................... 39

4.4. Air Quality Planning. ............................................................................................... 39

4.5. Air Quality Compliance - Implementation and Operation. ...................................... 44

4.6. Air Quality Self-Assessment and Corrective Action ............................................... 47

4.7. Air Quality Management Review ............................................................................ 48

4.8. Air Quality Records Management. ......................................................................... 48

CHAPTER 5—HAZARDOUS WASTE (HW) MANAGEMENT 50

5.1. General Requirements. ............................................................................................. 50

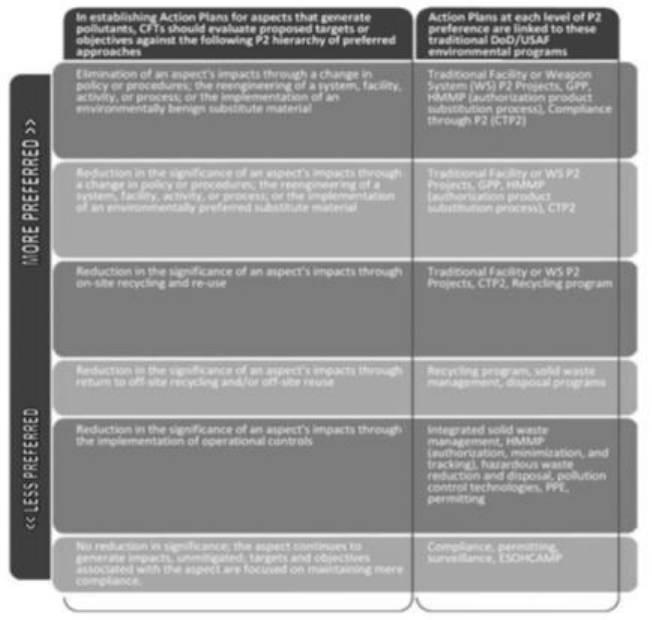

Table 5.1. Pollution Prevention Methodology. ......................................................................... 51

5.2. Hazardous Waste Management Plan (HWMP). ...................................................... 51

5.3. Waste Characterization and Identification. .............................................................. 52

5.4. Disposal Contracts. .................................................................................................. 54

5.5. Host-Tenant Support. ............................................................................................... 55

5.6. Hazardous Waste (HW) Implementation and Operation. ........................................ 56

5.7. HW Self-Assessment and Corrective Action. .......................................................... 59

CHAPTER 6—INTEGRATED SOLID WASTE MANAGEMENT 60

6.1. General Requirements. ............................................................................................. 60

6.2. Integrated Solid Waste Management (ISWM) Plan. ............................................... 60

6.3. Recordkeeping and Reporting. ................................................................................. 60

AFMAN32-7002 4 FEBRUARY 2020 5

6.4. Handling, Storage, and Collection. .......................................................................... 61

6.5. Municipal Solid Waste (MSW). .............................................................................. 61

6.6. SW Diversion. .......................................................................................................... 62

6.7. Defense Working Capital Fund Activities. ............................................................. 65

6.8. Construction and Demolition (C&D) Debris. .......................................................... 65

6.9. Asbestos-contaminated C&D Management ............................................................. 65

6.10. Lead Based Paint (LBP)-Contaminated Construction & Demolition Debris

Management ............................................................................................................. 66

CHAPTER 7—TOXICS MANAGEMENT 67

7.1. Toxic Substances Control Act (TSCA). .................................................................. 67

7.2. Management of Individual Toxics. ......................................................................... 67

7.3. Emergency Planning and Community-Right-to-Know Act (EPCRA)

Management ............................................................................................................. 73

Attachment 1—GLOSSARY OF REFERENCES AND SUPPORTING INFORMATION 76

Attachment 2—WASTE MANAGEMENT COMPLIANCE STATUTES AND

REGULATIONS 101

Attachment 3—AIR EMISSION REDUCTION CREDITS 103

6 AFMAN32-7002 4 FEBRUARY 2020

Chapter 1

INTRODUCTION

1.1. Overview. This publication establishes directive guidance and procedures for AF-wide

environmental compliance and pollution prevention management. AF organizations at all levels

must follow this manual to ensure uninterrupted access to the air, land, and water assets needed to

conduct the AF mission.

1.2. Scope. This AFMAN directs the Air Force Civil Engineer Center (AFCEC), the primary

support unit under the Air Force Installation and Mission Support Center (AFIMSC), and

installations to establish and maintain compliance and pollution prevention programs to comply

with all applicable federal, state and local environmental laws and standards.

1.2.1. Follow state and local laws consistent with federal government waiver of sovereign

immunity.

1.2.2. Follow more stringent environmental compliance requirements under applicable state

and local standards.

1.2.3. AF installations located outside the U.S. must implement this AFMAN consistent with

applicable international agreements, Unified Combatant Command (UCC) policy,

environmental annexes to operational orders or plans, and country-specific final governing

standards (FGS), or in their absence, the Overseas Environmental Baseline Guidance

Document (OEBGD). (T-1). In case of conflict, applicable international agreements, UCC

policy, the environmental annex, the FGS, or the OEBGD takes precedence over this AFMAN.

1.3. Statutes and Regulations. See Attachment 1 for a list of pertinent statutes and regulations

and Attachment 2 for a list of waste management statutes and regulations, including Public Law

102-386, Federal Facility Compliance Act. The compliance and pollution prevention programs

included in this manual will consider media-specific impacts related to AF activities and ensure

compliance with applicable environmental legal requirements. Therefore, in accordance with

AFPD 32-70, and consistent with DoDI 4715.06, Environmental Compliance in the United States,

DoDI 4715.05, Environmental Compliance at Installations Outside the United States, and DoDI

4715.23, Integrated Solid Waste Management, AFCEC and AF installations shall establish and

maintain the environmental media area programs outlined below.

1.3.1. Air Quality. An Air Quality Compliance Program (Air Quality Program) that governs

the operation of all AF stationary, mobile, and transitory sources of air pollution. (T-0). This

will provide data for basing and operational decisions; and assess, attain, and maintain

compliance with applicable federal, state and local air quality standards associated with 42

USC §§ 7401-7671q, Clean Air Act (CAA), for AF installations.

1.3.2. Hazardous Materials Management. A cross-functional program that governs the

procurement, management and use of hazardous materials through a hazardous process

authorization in order to: (1) support AF mission requirements; (2) protect the safety and health

of personnel on AF installations and communities surrounding AF installations; (3) achieve

pollution prevention objectives by minimizing AF dependence on hazardous materials, while

reducing associated total ownership costs; and (4) maintain AF compliance with environmental

pollution prevention and reporting requirements. (T-1). In order to comply with Executive

Order (E.O.) 13834, Efficient Federal Operations, AF installations located in the United States

AFMAN32-7002 4 FEBRUARY 2020 7

will comply with hazardous material reporting requirements of 42 USC §§ 11001-11050,

Emergency Planning and Community Right-to-Know Act, as implemented by the United States

Environmental Protection Agency (EPA). (T-0).

1.3.3. Water Quality. A Water Quality program to ensure water quality management takes into

account impacts on water quality from AF activities and that such activities comply with all

applicable permit standards under the National Pollutant Discharge Elimination System. This

refers to point source and non-point source water discharge standards in accordance with The

Federal Water Pollution Control Act, as amended by 33 USC §§ 1251–1386, The Federal

Water Pollution Control Act,. (T-0). Reference state or local requirements and follow the AFI

32-1067, Water and Fuel Systems, for water quality requirements impacting civil engineer

wastewater and storm water utilities management.

1.3.4. Safe Drinking Water. A Drinking Water Surveillance Program on base that ensures AF-

owned or operated water production and treatment facilities are managed in a manner

compliant with 42 USC §§ 300f – 300j-26, The Safe Drinking Water Act and protects human

health and safety from AF mission activities. (T-0). Reference AFI 48-144, Drinking Water

Surveillance Program, for Safe Drinking Water Act sampling/monitoring requirements, and

AFI 32-1067 for operational requirements impacting AF drinking water systems.

1.3.5. Storage Tanks. A Storage Tank Program to prevent spills and ensure AF mission

operations are conducted in compliance with federal and applicable state and local

environmental regulations. (T-0). Federal requirements are primarily under Title 40 Code of

Federal Regulations (CFR) Part 112, Oil Pollution Prevention, and 40 CFR Part 280, Technical

Standards and Corrective Action Requirements for Owners and Operators of Underground

Storage Tanks. Overseas locations will establish a Storage Tank Program in accordance with

country-specific FGS, the OEBGD, if no FGS exists, or applicable provisions of an

international agreement (T-0). Fuel Infrastructure (e.g., storage tanks and associated piping,

transfer terminals, hydrant systems and pipelines), operated and maintained in accordance with

environmental regulatory requirements, perform an essential function in support of the AF

mission. Where petroleum and hazardous substances are necessary for use by the AF mission,

these may be stored in underground or aboveground storage tanks. Additional standards and

directive guidance can be found in AFI 23-201, Fuels Management; AFI 23-204,

Organizational Fuel Tanks; Unified Facilities Criteria (UFC) 3-460-01 Design: Petroleum

Fuel Facilities; UFC 3-460-03 O&M: Maintenance of Petroleum Systems; National Fire

Protection Association, Petroleum Equipment Institute; Steel Tank Institute; American

Petroleum Institute; National Electric Code; and the Occupational Safety and Health

Administration (OSHA).

1.3.6. Waste Management. The program to minimize or eliminate the volume and toxicity of

solid waste (SW) and HW generated from AF operations in accordance with 42 USC §§ 6901-

6992, Solid Waste Disposal Act and the Resource Conservation and Recovery Act (RCRA).

Implement the program’s key element of risk reduction, and maximize efficiencies while

supporting the mission, as follows:

1.3.6.1. Integrated Solid Waste Management (ISWM). Establish, implement, and maintain

an (ISWM) Program to maximize the recovery or diversion of SW (including construction

and demolition debris) from landfills in accordance with DoDI 4715.23. (T-0). For

overseas installations, the AF shall operate and maintain an ISWM in accordance with

8 AFMAN32-7002 4 FEBRUARY 2020

DoDI 4715.23, country-specific FGS or the OEBGD, if no FGS exists, or applicable

provisions of an international agreement. (T-0).

1.3.6.2. Qualified Recycling. Installation ISWM programs that retain the proceeds from

the sale of recyclable materials shall establish and maintain a single Qualified Recycling

Program in accordance with 10 USC § 2577, Disposal of Recyclable Materials, 32 CFR

Part 172, Disposition of Proceeds From DoD Sales of Surplus Personal Property, and

DoDI 4715.23. (T-0).

1.3.6.3. Hazardous Waste (HW). Establish and maintain a HW management program that

ensures compliance with all applicable federal, state, and local laws and regulations (40

CFR Part 260-273, Hazardous Waste Management System), DoDI 4715.06, and other

DoD/AF policies. (T-0). Use a HW management plan to document installation processes/

procedures. (T-1). Overseas locations establish and maintain a HW management program

in accordance with DoDI 4715.05, country-specific FGS, the OEBGD, if no FGS exists,

or applicable provisions of an international agreement. (T-0).

1.3.7. This AFMAN does not address radioactive waste (RW) (except mixed waste), medical

waste, or radon. Radioactive waste is addressed in AFMAN 40-201, Radioactive Materials

(RAM) Management. Medical waste is addressed in AFI 41-201, Managing Clinical

Engineering Programs. Radon is addressed in AFI 48-148, Ionizing Radiation Protection.

Note: Certain medical waste and expired and unused pharmaceuticals intended to be disposed

can meet the definition of HW, and therefore its management is governed by the Resource

Conservation and Recovery Act and this AFMAN.

1.3.8. See Attachment 2 for an outline of federal regulations and laws related to Waste

Management.

1.4. Environmental Management System (EMS). Consistent with E.O. 13834, and in

accordance with DoDI 4715.17, Environmental Management System; AFPD 90-8, Environment,

Safety, & Occupational Health Management and Risk Management; and AFPD 32-70, AF

installations are directed to use an EMS framework to sustain, restore, and modernize natural and

built infrastructure assets to support mission capability. (T-0). Installation commanders or

Installation Environment, Safety, and Occupational Health Councils will ensure the environmental

media programs outlined above are operated within this EMS framework consistent with AFPD

32-70 and using the AF guidance contained in AFI 32-7001. (T-1). AFI 32-7001 provides the EMS

methodology, specifies use of standardized automated tools on AFCEC’s SharePoint® site,

eDASH (Virtual Environmental Management Office for the ANG bases), requires use of AFCEC

environmental planning templates, and outlines environmental/natural infrastructure reporting

requirements. The EMS framework thus allows AF and installations to appropriately plan,

implement, operate, check, and monitor all facets of activities necessary in a cycle of continual

improvement. This Plan-Do-Check-Act cycle can best be used to manage natural infrastructure

assets and apply pollution prevention methodologies to achieve compliance while ensuring

installation readiness and sustaining mission capability.

AFMAN32-7002 4 FEBRUARY 2020 9

Chapter 2

ROLES AND RESPONSIBILITIES

2.1. Deputy Assistant Secretary of the Air Force for Environment, Safety, and

Infrastructure (SAF/IEE). SAF/IEE:

2.1.1. Establishes overarching AF environmental policy directing establishment of regulatory

media area programs to consider media-specific impacts related to AF activities. It also ensures

installation environmental compliance, risk reduction, and continuous improvement in

business processes which supports installation and mission resilience, efficiency, conservation,

and innovation.

2.1.2. Provides coordination, integration and oversight of DoD environmental compliance

strategy and emergent issues, to include assessment of execution of AF environmental

programs described in this manual.

2.1.3. Develops the enterprise strategies, priorities, goals, and metrics in coordination with the

Deputy Chief of Staff for Logistics, Engineering and Force Protection, Directorate of Civil

Engineers (AF/A4C), to track and analyze Major Command (MAJCOM) and installation

investment and execution of environmental compliance and the prevention of pollution.

2.1.4. Serves as the principal AF representative on all environmental management issues for

formal interactions with staff from the Office of the Secretary of Defense, federal agencies,

and Congress, to include CAA National Security Exemptions (NSE) claimed by the AF and

being informed of interactions and agreements made with external environmental

organizations.

2.1.5. Approves each AF CAA General Conformity Determination prior to release for public

review and prior to finalization.

2.1.6. Reviews all requests for the payment of state punitive fines and penalties assessed under

the waiver of federal sovereign immunity under the CAA (See Paragraph 4.8.4).

2.1.7. Provides oversight of the Headquarters Air Force (HAF) Hazardous Material

Management Process (HMMP) team consisting of representatives from the Weapon Systems

acquisition and the Environmental, Safety, and Occupational Health communities that report

to the HAF Environment, Safety, and Occupational Health Steering Committee (ESOH SC).

2.2. The General Counsel of the Department of the Air Force (SAF/GC), through the Deputy

General Counsel for Installations, Energy and Environment (SAF/GCN). SAF/GCN:

2.2.1. Provides legal advice to the Secretary of the AF concerning all matters associated with

environmental laws and other applicable legal requirements.

2.2.2. Serves as the principal legal adviser to SAF/IEE on environmental compliance policy,

including resolution of final enforcement action decisions, settlement of punitive fines and

penalties, and determinations of invocation or waiver of Federal sovereign immunity.

Depending on the legal issues and governing documents relating to the issues, SAF/GC

consults with the Air Force Legal Operations Agency (AFLOA) or other legal service

providers.

10 AFMAN32-7002 4 FEBRUARY 2020

2.2.3. Reviews and advises SAF/IEE on the legal sufficiency of all draft and final CAA

General Conformity Determinations after consultation with AFLOA/JACE on potential

litigation risks.

2.2.4. Nothing in this Paragraph is inconsistent with HAF Mission Directive (HAFMD) 1-14,

General Counsel and The Judge Advocate General.

2.3. Assistant Secretary of the Air Force for Acquisition, Technology, and Logistics

(SAF/AQ). SAF/AQ:

2.3.1. Incorporates environmental risk management into systems engineering and the

acquisition decision-making process, consistent with HAF Mission Directive 1-18, Assistant

Secretary of the Air Force (Installations, Environment and Energy), AFPD 32-70, and AFI 32-

7001.

2.3.2. Provides HAF-level management, with the Directorate of Logistics (AF/A4L), of the

AF account at the DoD Ozone Depleting Substances (ODS) Reserve.

2.3.3. Consults on Environmental contracting issues, sustainable procurement, and use of

Federal Acquisition contract clauses.

2.4. The Headquarters, United States Air Force, Deputy Chief of Staff for Logistics,

Engineering and Force Protection, Directorate of Civil Engineers (AF/A4C). AF/A4C:

2.4.1. Assists SAF/IEE on matters related to policy, strategy, direction and oversight,

including governance, to execute the environmental programs described in this manual.

2.4.2. Develops strategy and implementing policy guidance for the management and

programming investments for the environmental media areas described in this manual.

Consults with the AFCEC, ANGRC, AFRC, and HAF Environmental, Safety and

Occupational Health (ESOH) and Logistics functions on environmental strategy, guidance, and

performance monitoring.

2.4.3. Participates as the AF lead in DoD Environmental media-specific steering committees

on behalf of SAF/IEE, except primary representative for Safe Drinking Water Act committee

is assigned from the Air Force Medical Readiness Agency (AFMRA), Healthcare Operations

Directorate (SG3). Represents AF position/interests involving DoD feedback on federal and

state legislation/regulations, executive order implementation, and DoD policies which effect

installation environmental management and resiliency.

2.4.4. Provides oversight of training and performance monitoring for installation

environmental compliance and pollution prevention programs, to include consultation and

oversight of Air Force Institute of Technology (AFIT) Environmental Courses.

2.4.5. Incorporates environmental compliance requirements into civil engineer processes

through guidance, procedures, and training.

2.4.6. Partners with the Air Force Surgeon General (AF/SG) to ensure Safety Data Sheet

(SDS) data management meets both Hazard Communication Standard and hazardous material

tracking system requirements.

2.4.7. Integrates ODS management and conservation into installation and facility management

policies, procedures, and training.

AFMAN32-7002 4 FEBRUARY 2020 11

2.4.8. Provides core membership and administrative lead for CE Governance, to include the

Environmental Program Working Group; provides environmental program manager oversight

of environmental panels established under the Environmental Program Working Group.

2.4.9. Leads the HAF HMMP team consisting of representatives appointed by SAF/AQ, Air

Force Chief of Safety (AF/SE), AF/SG, and the AF, Deputy Chief of Staff for Logistics,

Engineering, & Force Protection, Directorate of Logistics (AF/A4L); and reports to the HAF

ESOH SC to identify and resolve hazardous material management issues, particularly in

implementing policy and ensure visibility by cross-feeding best practices from the field.

2.5. The Headquarters, United States Air Force, Deputy Chief of Staff for Logistics,

Engineering, & Force Protection, Directorate of Logistics (AF/A4L). AF/A4L:

2.5.1. Provides policy and guidance necessary to align responsibilities and procedures in this

document with Logistics and Maintenance directive guidance.

2.5.2. Establishes sustainable hazardous material transportation and air quality compliance

guidance associated with Air Force Fleet Vehicle management, with centralized execution

through the 441st Vehicle Support Chain Operations Squadron at Joint Base Langley-Eustis,

VA.

2.5.3. Establishes hazardous material (HAZMAT) procurement data requirements and

procedures to collect data for reporting requirements.

2.5.4. Integrates environmental risk management and hazardous material/HW procedures into

weapon system maintenance and logistics readiness processes, investment and decision-

making.

2.5.5. Incorporates HMMP requirements into material management and maintenance

processes through policies, procedures, and training.

2.5.6. Advocates for the resources (funding and personnel) required so installation supply and

maintenance functions can execute their HMMP responsibilities.

2.5.7. Incorporates appropriate hazardous material substitution processes into weapon system

deficiency reporting and Technical Order change policy and guidance.

2.5.8. Works with SAF/AQ to manage the AF account at the DoD or Defense ODS Reserve

operated by the Defense Logistics Agency (DLA) and to ensure HAF-level management of

out-of-production ODS reflects A4 sustainment priorities.

2.5.9. Ensures A4 personnel receive education and training on requirements related to the

storage, handling and transportation of hazardous material and HW as well as operating air

emission sources.

2.5.10. Provides logistics readiness and maintenance participation in the HAF HMMP team.

2.6. The Headquarters, United States Air Force, Surgeon General (AF/SG). AF/SG:

2.6.1. Incorporates environmental compliance and pollution prevention requirements into SG

processes through policies, procedures, and training.

2.6.2. Serves as the AF office of primary responsibility (OPR) for SDS issues and data

management needs with respect to the OSHA Hazard Communication Standard.

12 AFMAN32-7002 4 FEBRUARY 2020

2.6.3. Partners with AF/A4C and AFCEC to ensure adequate sampling, analysis and

monitoring programs are implemented to meet compliance requirements for regulations

impacting the environmental media areas described in this manual.

2.6.4. Provides AF/SG participation in the HAF HMMP team.

2.6.5. Serves as the AF focal point for Safe Drinking Water Act issues.

2.7. The Headquarters, United States Air Force, Chief of Safety (AF/SE). AF/SE:

2.7.1. Incorporates environmental compliance and pollution prevention requirements into AF/

SE processes through policies, procedures, and training.

2.7.2. Provides AF/SE participation in the HAF HMMP team.

2.8. Headquarters, United States Air Force, The Judge Advocate General (AF/JA) through

the Air Force Legal Operations Agency, Civil Law and Litigation Directorate,

Environmental Law and Litigation Division (AFLOA/JACE). AFLOA/JACE:

2.8.1. Provides legal expertise to HAF, MAJCOMs, reserve components, AFIMSC, AFCEC

and installations on all applicable laws, regulations, and E.O. requirements impacting AF

hazardous material and environmental policy implementation.

2.8.2. Provides legal expertise on applicability of this manual to locations outside the U.S. to

ensure there is no conflict with applicable country-specific FGS or, in countries where no FGS

exist, the Overseas Environmental Baseline Guidance Document (OEBGD), and UCC

directives.

2.8.3. Ensures coordination with Department of Justice, SAF/IEE, and SAF/GCN regarding

the payment of CAA or other applicable penalties. Provides approval before settlement of any

administrative action where the terms of the settlement include provision for the payment of

fines or supplemental environmental projects. The appropriate Regional Counsel Office (East

or West), established under AFLOA/JACE, will assist in resolving enforcement actions

processed against AF installations.

2.8.4. Assists in the review and validation of all proposed air quality NSEs and coordinates

with SAF/GCN, SAF/IEE and AF/A4C as warranted.

2.8.5. Nothing in this Paragraph is inconsistent with HAF Mission Directive (HAFMD) 1-14,

General Counsel and The Judge Advocate General.

2.9. The Chiefs of the National Guard Bureau (NGB) and Air Force Reserve Command

(AFRC). NGB and AFRC will:

2.9.1. Develop additional guidance or instructions as applicable, to meet unique operational

and mission needs, and ensure adequate oversight of the environmental media areas in this

manual.

2.9.2. Perform the roles and responsibilities performed by the Air Force Civil Engineer Center,

Environmental Directorate (AFCEC/CZ) for AFR installations, except for appropriate subject

matter expert (SME) roles/responsibilities.

2.9.3. Participate as a member of each AFCEC environmental media panel.

AFMAN32-7002 4 FEBRUARY 2020 13

2.9.4. The Air National Guard, Logistics and Installation Directorate, Asset Management

Division, Environmental Branch (NGB/A4AN) provides program guidance and manages

ANG’s organizational/multi-site environmental management system to ensure compliance,

reduce risk, and continual improvement.

2.10. Major Command (MAJCOM) or Air National Guard Readiness Center (ANGRC)

Commander and/or Environment, Safety, and Occupational Health Council (ESOHC)

Chair. ESOHC chairs will:

2.10.1. Monitor environmental performance and provide oversight and direction to installation

commanders through the installation ESOHCs to maintain compliance or implement corrective

actions on a timely basis to minimize environmental deficiencies.

2.10.2. Implement a culture of compliance and excellence to enable Airmen to carry out

activities across all AF mission areas that might impact the environment.

2.10.3. All references to Commands in this AFMAN include the ANGRC and other agencies

that HAF designates as “Major Command equivalent”. As needed, Commands will provide

administrative, technical, and resource advocacy support to ensure installations comply with

AF policies and regulatory requirements.

2.11. Air Force Installation and Mission Support Center (AFIMSC). AFIMSC:

2.11.1. Provides resource advocacy, and plan, program, and budget for AF environmental

Operations and Maintenance (O&M) programs.

2.11.2. Assists AF installations in delivering the capabilities to implement facility

environmental strategic policy, guidance, and environmental reporting.

2.12. The Air Force Civil Engineer Center, Environmental Directorate

(AFCEC/CZ). AFCEC/CZ, a Primary Subordinate Unit to the AFIMSC, provides execution

support to RegAF installations in order to implement this AFMAN, consisting of subject matter

expertise, issuing supplemental guidance, allocating resources, and overseeing execution of the

environmental management process throughout the AF. The AFCEC, Environmental Directorate

(AFCEC/CZ), will:

2.12.1. Provide SMEs to serve as AF-wide authoritative experts for each major Environmental

Compliance Program, establishing and updating procedures, tracking and analyzing overall

environmental compliance, and developing enterprise-level compliance strategies and

continuous improvement initiatives. (T-1). Specific responsibilities will include, but not be

limited to:

2.12.1.1. Serving as the program management office for the standard AF Air Quality

Tracking System, Air Program Information Management System (APIMS) and support to

the program management office and functional management office for the Enterprise

Environmental, Safety, and Occupational Health Management Information System

(EESOH-MIS). (T-2). Coordinate with NGB/A4AN and Air Force Reserve Command,

Environmental & Asset Accountability Branch (AFRC/A4A) for the development and

update of environmental databases within AFCEC purview which would impact AFR

components.

2.12.1.2. Ensuring technical support for environmental compliance related requirements,

including capability to interface with or carry out activities at the RegAF installations in

14 AFMAN32-7002 4 FEBRUARY 2020

the U.S. and territories, or directly interface with ANGRC, AFRC, and overseas

installations. (T-2). (Note: United States Air Forces Europe and Pacific AF installations

are supported by AFCEC/CF Europe and Pacific divisions.)

2.12.1.3. Assisting in the collection, quality assurance, and analysis of environmental

compliance data, consistent with AFI 32-7001, as follows:

2.12.1.3.1. Develop and maintain program-wide key performance indicators and

performance metrics, data requirements, and schedules in order to perform trend

analysis and conduct compliance assessments. (T-2).

2.12.1.3.2. Collect, consolidate, and maintain installation-level environmental

compliance performance data, to include enterprise-level (AF-wide) performance data

needed for the Defense Environmental Programs Annual Report to Congress

(DEPARC) and Office of the Secretary of Defense and for AF environmental

management reviews. (T-0).

2.12.1.3.3. Track, assess, and communicate new or emerging regulatory requirements

for their potential impact on installation operations. (T-2).

2.12.1.4. Developing enterprise level (AF-wide) environmental compliance and resource

management education and training. (T-2). Where feasible, pursue cost-effective non-

traditional education and training methodologies (e.g., correspondence and webinar

training).

2.12.1.5. Reviewing, validating, and approving proposed NSE and NSE endorsements. (T-

1). Only the SME will provide final approval of “automatically exempt” (without request)

or proposed NSE endorsements under 40 CFR Part 1068, General Compliance Provisions

for Engine Programs. (T-1). Process NSE requests requiring EPA approval or that are

precedence setting or have potential for high visibility in accordance with the latest DoD

and AF policies and guidance. Ensure the originating organization or AFCEC/CZ

coordinates with the Civil Engineer-Installation Management, Environmental Element,

AFLOA/JACE, and higher headquarters (AF/A4C, SAF/IEE, and SAF/GCN). (T-1).

2.12.1.6. Ensuring current installation Air Emission Inventories (AEI) and Potential-to-

Emit (PTE) emissions inventories are performed and maintained in accordance with this

manual AEI guidance, and 40 CFR Part 51, Subpart A, Air Emissions Reporting

Requirements. (T-0). Additionally, ensure AEIs and PTE contributions are explicitly

documented in APIMS and emission budget updates are provided to state authorities as

part of the recurring SIP revision process applicable to the installation. (T-1).

2.12.1.7. Providing AF-wide Air Quality Program non-directive guidance, standardized

best compliance practices or methodologies, in the form of civil engineer Playbook content,

or other means, for critical (i.e., high regulatory risk) air quality areas. (T-1). Includes:

2.12.1.7.1. AEI guidance for AF sources relaying standardized procedures and

methodologies for estimating emissions for AEI (per 40 CFR Part 51, Subpart A); to

include mobile, stationary, transitory, PTE, and all other sources of air emissions.

2.12.1.7.2. Air Quality guidance for implementation of 32 CFR Part 989,

Environmental Impact Analysis Process (EIAP), and General Conformity guidance in

accordance with 40 CFR Part 51, Subpart W, Determining Conformity of General

AFMAN32-7002 4 FEBRUARY 2020 15

Federal Actions to State or Federal Implementation Plans and 40 CFR Part 93,

Subpart B, Determining Conformity of General Federal Actions to State or Federal

Implementation Plans.

2.12.1.7.3. An attainment status list of AF installations and facilities, through on-going

review of U.S. CFRs, for use in permitting, EIAP, and Conformity Rules assessment.

2.12.1.7.4. Greenhouse Gas guidance on standardized procedures and methodologies

for estimating emissions, to include mandatory reporting in accordance with 40 CFR

Part 98, Mandatory Greenhouse Gas Reporting and DoD compliance with greenhouse

gas requirements under E.O. 13834.

2.12.1.7.5. Emerging issues analysis and guidance on new and emerging regulatory

requirements to assess impacts on the mission and ensure compliance, in the form of

an annual emerging issues assessment report. For emerging regulatory requirements,

identify and establish appropriate guidance prior to the promulgation of the regulation.

2.12.1.8. Developing enterprise-level non-directive air quality compliance guidance for

key source categories within civil engineering. (T-2). Includes the following:

2.12.1.8.1. Internal Combustion Engine sources in accordance with 40 CFR Part 63,

National Emission Standards for Hazardous Air Pollutants (NESHAP) for Source

Categories, in particular Reciprocating Internal Combustion Engines; and 40 CFR Part

60, Standards of Performance for New Stationary Sources, especially related to

Stationary Spark and Stationary Compression Ignition, Internal Combustion Engines..

2.12.1.8.2. Boilers and process heaters in accordance with 40 CFR Part 63, NESHAP,

for major Source Categories such as Industrial, Commercial, and Institutional Boilers

and Process Heaters, and Industrial, Commercial, and Institutional Boilers Area

Sources.

2.12.1.8.3. Refrigerant management to expand on requirements in 40 CFR Part 82,

Protection of Stratospheric Ozone.

2.12.1.8.4. Other key source categories as determined by the AFCEC SME.

2.12.2. Cross-feed best practices and standardized Environmental Compliance programs

across the AF. (T-2).

2.12.3. Plan, program, and budget environmental compliance requirements for applicable

programs described in this manual in accordance with AFI 32-7001. (T-1).

2.12.4. Validate enforcement actions, host nation enforcement actions, or notices of

violations, and tracks until closure, in accordance with AFI 32-7001. (T-1). As stated in AFI

32-7001, SMEs review management action plans to ensure outstanding open enforcement

actions are resolved within the required time frames; review the response to regulatory agency

inspection findings to ensure process owners take timely corrective actions and implement

appropriate preventive measures; and ensure reporting timelines outlined in AFI 32-7001 are

followed.

2.12.5. Ensure installations use the Environmental Management System (EMS) framework in

accordance with AFI 32-7001, to build a management strategy for each environmental

compliance media area addressed in this manual to support mission capability by ensuring the

16 AFMAN32-7002 4 FEBRUARY 2020

sustainment, restoration, and modernization of natural and built infrastructure assets. (T-1).

This includes using eDASH/VEMO as the primary repository for the storage of environmental

documentation and/or ensuring other systems include links to eDASH as the authoritative

source.

2.12.6. When requested, can represent the AF on a regional basis, to federal, state, and local

environmental regulatory agencies. This includes being the lead liaison office on behalf of

installations for interfacing with regulatory agencies and other internal/external audit

personnel, on matters requiring environmental compliance expertise or involving resource

management issues.

2.12.7. Review all permits, permitting requirements, and associated federal, state, local

Resource Conservation and Recovery Act (RCRA) regulations (40 CFR Parts 239-282) or

CAA regulations (40 CFR Parts 50-98, Air Programs), for waste management and air quality

compliance respectively, or equivalent host nation requirements (overseas), to ensure

compliance conditions are met for both current mission operations and projected mission

growth. (T-1). This includes maintaining an updated summary of all permit requirements for

installations, with a comparison to the regulatory requirements and schedules; and in

coordination with the installation, ensuring that all required permits are applied for,

maintained, updated, and signed by an appropriate official.

2.12.8. Consult with Environmental Planners and base civil engineering on air quality and

waste management impacts as early as practicable to ensure timely EIAP assessments under

the National Environmental Policy Act (40 CFR Parts 1500-1508, Council on Environmental

Quality) process for Military Construction (MILCON) and non-MILCON projects. (T-2). This

includes preparing and submitting all necessary environmental permits and related fees within

project funding constraints. (T-2).

2.12.9. Review all AF General Conformity Determinations before submission to SAF/IEE and

SAF/GCN for approval to ensure installations in CAA nonattainment or maintenance areas

comply with the Conformity Rules in accordance with this AFMAN, 40 CFR Part 51, Subpart

W; 40 CFR Part 93, Subpart B. Additional non-directive guidance on AF application of the

CAA Conformity Rule is available from AFCEC/CZ. (T-0).

2.12.10. Maintain an authoritative CAA attainment status list under the NAAQS of AF

installations and facilities, through on-going review of the U.S. CFRs, for use in permitting,

EIAP, and Conformity Rules assessment. (T-2).

2.12.11. Develop refrigerant management non-directive guidance to meet requirements under

the CAA (40 CFR Part 82). (T-1).

2.12.12. Ensure coordination through the appropriate chain-of-command of any comments on

federal, state, and local proposed rulemaking, revisions, plans, protocols, and permits. (T-1).

Consult with higher headquarters on negotiations with federal, state, and local regulatory

agencies regarding installation-specific issues (e.g., variances, permit limits, and operating

conditions). (T-1).

2.12.13. Track, assess, and report new or emerging regulatory requirements for potential

impact on installation operations. Ensures any such requirements are incorporated into

appropriate program elements and reports identified impacts through the chain of command.

(T-2).

AFMAN32-7002 4 FEBRUARY 2020 17

2.12.14. Use AFI 90-201, Air Force Inspection System, and the Management Internal Control

Tool (MICT) as a tool for assessing and monitoring AF compliance, and identifying and

prioritizing recommended corrective actions as necessary. (T-1).

2.12.15. Provide regulatory and legislative support by serving as a technical and regulatory

advisor to the SAF/IEE, AF/A4C, AFRC, and ANG. (T-1). Monitors environmental

compliance regulatory initiatives developed by the EPA and state agencies. (T-1).

2.12.16. Provide guidance and technical expertise for the AF Hazardous Materials

Management Process (HMMP) as follows:

2.12.16.1. Provide guidance to installations to ensure that outsourcing and privatization

initiatives involving any of the HMMP team responsibilities explicitly spell-out those

responsibilities in the contract. (T-2).

2.12.16.2. Develop and maintain an AF HMMP web page and HMMP guidance on

AFCEC’s SharePoint® site, eDASH, to enhance information exchange. (T-1).

2.12.17. Plan, program, and advocate for civil engineer-related HMMP responsibilities

consistent with environmental budgeting guidance in AFI 32-7001. (T-1).

2.12.18. Establish a Hazardous Material Data Steward for EESOH-MIS to centrally create and

manage Safety Data Sheets and associated product hazard data for EESOH-MIS and to be in a

position to transfer SDS information to the AF SDS Focal Point in accordance with AFI 90-

821, Hazard Communication (HAZCOM) Program. (T-1). Posture the AF to adequately

convey hazardous material information to Defense Logistics Agency’s (DLA) Hazardous

Material Data Management System consistent with DoDI 6050.05, DoD Hazard

Communication (HAZCOM) Program.

2.12.19. Serve as the single, AF-wide authoritative expert for installation SW qualified

recycling programs, solid and HW compliance, and waste minimization. (T-2). This includes

establishing and updating waste management procedures, performing program analysis for

process improvement, reporting and establishing environmental compliance and pollution

prevention metrics, and establishing requirements for investment in pollution prevention.

2.12.20. Serve as a focal point for environmental regulatory expertise and information related

to toxic areas, including Polychlorinated Biphenyls (PCB), Emergency Planning and

Community Right-to-Know Act (EPCRA), and Toxic Substances Control Act (asbestos, lead-

based paint, etc.). (T-2).

2.12.21. Support the installation by arranging and completing Operational Range Assessments

in accordance with DoDI 4715.14, Operational Range Assessments. (T-0).

2.12.22. Partner with AFMSA/SG3 where appropriate to ensure adequate sampling, analysis

and monitoring programs are implemented to meet compliance requirements for regulations

impacting the environmental media areas described in this manual. (T-1).

2.13. AFCEC Operations, Energy, and Readiness Directorates (AFCEC/CO, CF, CN, and

CX), to the AFIMSC, will provide criteria, standards, procedural guidance, and technical

support for environmental compliance related activities to include air emission controls, the

execution of RCRA Military Munitions Rule (40 CFR Part 266, Subpart M, Standards for

The Management of Specific Hazardous Wastes and Specific Types of Hazardous Waste

Management Facilities: Military Munitions); waste management, and for environmental sources

18 AFMAN32-7002 4 FEBRUARY 2020

planning, design, construction, operations, maintenance, and contract management services to the

Air Staff, AFCEC, MAJCOMs, DRUs, and installations as requested. (T-1).

2.14. Installation/Center Commander. Installation/Center commander will:

2.14.1. Establish and maintain the environmental programs listed in Paragraph 1.3, in

accordance with DoDI 4715.06, Enclosure 2, Paragraph 5b. (T-0). Ensure environmental

compliance discipline and responsible resource management principles are emphasized to

Airmen and incorporated in installation activities. (T-3).

2.14.2. Ensure the installation environmental compliance program is managed to comply with

all applicable U.S. federal, state, and local requirements (including permits) associated with

waste management under 42 USC §§ 6901-6992, RCRA and air quality compliance under 42

USC §§ 7401-7671q, CAA. (T-0). For overseas installations comply with the applicable host-

nation FGS, or OEBGD, where no FGS exists. (T-0). Finally, applicable MAJCOM

Supplement, non-directive AFCEC playbooks or higher level DoDIs (e.g., DoDI 4715.06) can

also apply. ANG and AFRC installation Commanders will ensure there is an identified

environmental management POC dedicated to environmental compliance and management.

(T-2).

2.14.3. Ensure enforcement actions or host nation enforcement actions are promptly reported,

tracked, and managed in accordance with AFI 32-7001. (T-1).

2.14.4. Ensure installation organizations that award contracts with potential for using or

delivering hazardous materials or generating emissions or waste consult with the civil

engineering-Installation Management Flight, Environmental Element, or ANG Environmental

Management Office (see Paragraph 2.16.) to include environmental compliance requirements

and procedures in contract documents. (T-1).

2.14.5. For the Hazardous Materials Management Process (HMMP):

2.14.5.1. Establish a cross-functional HMMP team via formal charter under the

installation Environment, Safety, and Occupational Health Council (ESOHC) chair. (T-1).

Ensure core cross-functional members are appointed to the team as defined in Chapter 3,

Paragraph 3.2.

2.14.5.2. Require organizations on an installation ensure that the procurement of

hazardous materials follow Hazardous Material (HAZMAT) Tracking Activity (HTA)

guidelines and is authorized and tracked using the Enterprise, Environment, Safety, and

Occupational Health - Management Information System (EESOH-MIS) standard tracking

system. (T-1).

2.14.5.3. Ensure Unit Commanders properly dispose of excess hazardous materials,

including ensuring all excess Class I ozone depleting substances (ODS) and

Hydrochlorofluorocarbon-22 (HCFC-22, also called R-22) are returned to the ODS

Defense Reserve stockpile maintained by the DLA in accordance with DoDI 4715.06. (T-

0). Class I ODS includes Halon chemical compounds in liquefied, compressed gas form

used for fire-fighting operations.

2.14.6. For Air Quality Compliance and Resource Management:

2.14.6.1. In order to assure uninterrupted mission accomplishment at an installation, it is

important that installations establish and maintain an Air Quality Program governing the

AFMAN32-7002 4 FEBRUARY 2020 19

operation of all stationary and mobile sources of air pollution in order to assess, attain, and

maintain compliance with all applicable federal, state, and local air quality regulations and

permits.

2.14.6.2. Certify compliance with CAA Title V operating permit requirements, as the

“Responsible Official” under the CAA, 40 CFR Part 70, State Operating Permit

Programs, 40 CFR Part 71, Federal Operating Permit Programs, and applicable state or

local regulations. (T-0). This is accomplished by signing all CAA Title V permit

applications, certifying compliance with any other applicable operating and construction

permit requirements, and maintaining the authority to shut down any non-compliant air

emissions source on the installation. “Responsible Official” duties are not authorized to be

delegated to any subordinate official.

2.14.6.3. Ensure all installation organizations and tenant organizations (within the

installation’s command and control) that own air emission sources comply with applicable

federal, state, local, and installation air quality requirements under the CAA, and

coordinate any actions which affect air quality with base civil engineering or AF Reserve

Environmental Management Office. (T-0).

2.14.6.4. Ensure any organizations planning to purchase equipment that generates air

emissions with potential permitting, authorization, or registration requirements (e.g.,

degreasers, generators, boilers, painting, or abrasive blasting equipment), first coordinate

with the Base Civil Engineer (BCE). (T-1).

2.14.6.5. Ensure implementation of an installation Vehicle Inspection and Maintenance

Program in accordance with the CAA §118(d) for employee-owned vehicles driven on the

installation and CAA § 118(c) for government owned or leased vehicles. (T-0). See

Paragraph 4.7.3.1.2 for applicability.

2.14.7. For Hazardous Waste (HW) Management:

2.14.7.1. Ensure the installation, as a potential generator of HW, establishes a HW

program in accordance with AFPD 32-70, to ensure compliance with Chapter 5 of this

AFMAN, and all applicable federal, state, and local laws and regulations established under

42 USC §§ 6901-6992, RCRA. (T-0).

2.14.7.2. Ensure compliance with RCRA permit requirements/conditions (40 CFR Part

270, EPA Administered Permit Programs: The Hazardous Waste Permit Program), if the

installation owns a permit(s) for HW treatment, storage, and disposal facilities (TSDF). (T-

0). In the event of a conflict, permit requirements supersede the guidance in this AFMAN.

Installations minimize dependence on RCRA permits through waste minimization efforts

or use of alternate closed-loop treatment, if feasible.

2.14.7.3. Sign HW manifests for HW shipped off-site as required by 40 CFR Part 262,

Subpart B, Standards Applicable to Generators of Hazardous Waste: Manifest

Requirements Applicable to Small and Large Quantity Generators. (T-0). This

responsibility can be delegated as long as the installation commander ensures the signature

delegation remains with a qualified (trained) DoD employees (civilian, military, guard,

reserve, or foreign national), or appropriately assigned State employee in the case of ANG

installations. Exception: For installations where the entire environmental function is

20 AFMAN32-7002 4 FEBRUARY 2020

outsourced on a Base Operations Support contract, the installation commander may

designate a contract employee with appropriate training to sign HW manifests.

2.14.7.4. Ensure the installation accomplishes appropriate management and disposal of

military munitions or material potentially presenting an explosive hazard in accordance

with DoD Explosive Safety Board standards contained in Department of Defense Manual

(DoDM) 6055.09-M, DoD Ammunition and Explosives Safety Standards, DoDI 4140.62,

Material Potentially Presenting an Explosive Hazard, and compliance requirements of 40

CFR Part 266, Subpart M, Military Munitions; see also 40 CFR Parts 260-266, Hazardous

Waste Management System and 40 CFR Part 270. (T-0). Coordinate with AFCEC/CX for

policy and guidance interpretation and execution of the Military Munitions Rule as it

applies to Explosive Ordnance Disposal Operations and with AFCEC/CZ for policy and

guidance interpretation and execution of the Military Munitions Rule as it applies to Waste

Management activities, including handling of expended munitions scrap metal.

2.14.8. For SW Management:

2.14.8.1. Implement an Installation Solid Waste Management (ISWM) plan, which may

include a Qualified Recycling Program (QRP), in accordance with DoDI 4715.23 and

applicable federal, state and local regulatory requirements. (T-0). For overseas bases, meet

the applicable country-specific Final Governing Standard or OEBGD. (T-0).

2.14.8.2. Ensure the installation, or any designated contractor, obtains and complies with

all required permits for SW management, to include establishing or operating landfills,

using material recovery facilities, or for the handling, storage, and collection involving

composting, in order to ensure compliance with 40 CFR Part 258, Criteria for Municipal

Solid Waste Landfills and equivalent State/local implementing regulations. (T-0). This

includes performing any required maintenance and monitoring activities specified in the

permit.

2.14.8.3. Designate, in writing, a QRP manager and an alternate QRP manager, to oversee

the base QRP operation, if the base establishes a QRP in accordance with DoDI 4715.23.

(T-0).

2.14.8.4. Establish a QRP committee and a chair to ensure a process that allows review of

committee recommendations to include allocation of sales revenue received in accordance

with 32 CFR Part 172. (T-0).

2.15. Base Civil Engineer (BCE) will (RegAF Installations):

2.15.1. Ensure new construction or modifications to existing facilities, especially existing air

emission sources, are not initiated until appropriate EIAP assessments are completed and

permits are received from cognizant regulatory authorities in accordance with 40 CFR Part

70. (T-0).

2.15.2. Ensure air-conditioning and refrigeration equipment are constructed, installed,

operated, tested, repaired, and maintained in compliance with the CAA, specifically 40 CFR

Part 82, other applicable state/federal requirements; or for overseas installations in accordance

with country-specific FGS or, in their absence, the OEBGD. (T-0).

2.15.3. Additional non-directive operational guidance on refrigeration management to help

meet air quality compliance requirements is available from AFCEC.

AFMAN32-7002 4 FEBRUARY 2020 21

2.15.4. Ensure Refrigerant Managers use the refrigerant module within Air Program

Information Management System (APIMS) for all Refrigerant Management planning,

tracking, monitoring, and recordkeeping actions required for ensuring Air Quality Program

compliance. (T-1).

2.15.5. Act, in concert with AFCEC/CZ and installation Judge Advocate (JA), as the liaison

office for environmental compliance issues with regulatory agencies, in accordance with other

applicable policy. (T-3).

2.15.6. Ensure adequate recordkeeping processes on base in order to retain all environmental

related notices, certifications, HW manifests, Recycling or Waste disposal shipping

documents, audit results (on and off-base) and waste analyses, in accordance with

environmental regulatory recordkeeping requirements under 40 CFR Part 262, Subpart D:

Recordkeeping and Reporting Applicable to Small and Large Quantity Generators, AFMAN

33-363 and the AF Records Disposition Schedule. (T-0). This includes the HW manager

consulting with the base Records Custodian on appropriate records to track, and on the tracking

duration, for waste or potential waste that leaves the base for disposal or recycling.

2.15.7. Sign an agreement with DLA on HW contract services in accordance with DoD

Manual (DoDM) 4160.21, Defense Material Disposition, to include prescribed DLA format.

(T-0).

2.15.8. Ensure appropriate participation in any base QRP to include CE Operations and

Environmental. (T-1).

2.15.9. Ensure sufficient resources and support for integrated SW management activities, in

accordance with AFI 32-1001, Civil Engineer Operations, to include adding information

requirements in Performance Work Statements for obtaining waste information from

contractors as needed. (T-1).

2.15.10. Installation unit commanders owning waste generation or air pollution sources will

endeavor to reduce pollution at the source in accordance with principles of 42 USC §§ 13101-

13109, Pollution Prevention Act. (T-1).

2.16. The Civil Engineer-Installation Management Flight, Environmental Element (CEIE)

or AFR Component (ANG or AFRC) Environmental Management Office (hereafter referred

to as Installation Environmental Element), is the installation environmental function with

overall management and execution responsibility for the installation’s environmental

program and focal point for monitoring the installation’s compliance status with all

applicable federal, state, local, and host-nation requirements. The Installation Environmental

Element (under the oversight of AFCEC/CZ, excluding AFRC and ANG installations), or AFR

Component Environmental Element will:

2.16.1. Assist the installation commander to ensure compliance with all applicable U.S.

federal, state, and local requirements (including permits), or for overseas, the FGS, or OEBGD,

where no FGS exists. (T1). In coordination with AFCEC/CZ (or ANGRC or AFRC), act as

the liaison office for environmental compliance and resource management issues with

regulatory agencies, and with both internal and external audit personnel. (T-1). Conform to

applicable AF/DoD policies and instructions, MAJCOM Supplements, and

Playbooks/Standard Operating Procedures for best management practices.

22 AFMAN32-7002 4 FEBRUARY 2020

2.16.2. Identify and arrange for environmental sampling, analysis, and monitoring to support

environmental compliance on the installation, including as required for CAA driven

Compliance Monitoring under 40 CFR Part 58, Ambient Air Quality Surveillance and RCRA

compliance for generator waste determination under 40 CFR Part 261, Identification and

Listing of Hazardous Waste. (T-0). Ensure Quality Assurance in carrying out environmental

sampling and testing programs in accordance with DoDI 4715.15, Environmental Quality

Systems. (T-0). See AFI 32-7001.

2.16.3. Initiate, develop, submit, or participate in funding requests for environmental

compliance and resource management requirements, regardless of fund source. (T-1).

2.16.4. Establish local procedures and provide technical expertise with regard to

environmental compliance and resource management requirements. (T-2).

2.16.5. Complete installation Emergency Planning and Community Right-to-Know Act

reporting, notifications, and planning, along with other environmental reporting, as

appropriate, in accordance with DoDI 4715.06. (T-0). This includes overseeing proper

programming, recordkeeping, and reporting procedures, to enable timely regulatory

notifications of emissions, spills, and other environmental releases and events, and ensuring

adequate responses to the Office of the Secretary of Defense and AF data calls.

2.16.6. Provide education and training, to include shop level training, to meet applicable

federal, state, and local environmental compliance requirements. (T-3).

2.16.7. Assist the installation commander by reviewing all permits and permitting

requirements, and potentially applicable federal, state, and local requirements as necessary to

ensure compliance conditions are met for air quality compliance under 42 USC §§ 7401-7671q,

CAA and waste management under 42 USC §§ 6901-6992, RCRA, for both current mission

operations and projected mission growth. (T-0). Based on the permit review, the Installation

Environmental Element will initiate permit modifications or changes through AFCEC/CZ,

ANGRC or AFRC as needed. (T-1).

2.16.8. Coordinate with base civil engineering construction managers, MAJCOM proponents,

and AFCEC (or ANGRC or AFRC) MILCON project managers as early as practicable to

ensure all necessary environmental permits are planned and procured. (T-1). This includes

ensuring project managers and construction agents for MILCON projects appropriately plan

for project funds and permit fees.

2.16.9. Coordinate and accomplish EIAP and General Conformity assessments as early as

practicable with proponent organizations initiating AF actions. (T-3). See Paragraph 4.6.4.2

2.16.10. Ensure comments on federal, state, and local proposed rules, revisions, plans,

protocols, permits, and negotiations with federal, state, and local regulatory agencies regarding

installation-specific issues (e.g., variances, permit limits and operating conditions) are

coordinated through the chain-of-command, including with AFCEC/CZ. (T-1).

2.16.11. Coordinate permits, open enforcement actions (EAs), and other applicable documents

and actions with the installation JA office and AFCEC/CZ. (T-1). For ANG and AFRC, also

coordinate with the MAJCOM JA. (T-2).

AFMAN32-7002 4 FEBRUARY 2020 23

2.16.12. Coordinate with the installation contracting function to ensure the applicable

regulatory requirements clauses and other appropriate conditions (E.O.s, directives, AF

requirements, etc.) are included in all contracts. (T-1).

2.16.13. Coordinate with Base Bioenvironmental Engineer (BEE) on any environmental

episodes or issues (e.g. spills, leaks, releases, compromised storage tank integrity, new

emissions sources, or changes to existing emissions sources) that could potentially require an

occupational and environmental health risk assessment. (T-1). This is done in accordance with

AFI 48-145, Occupational and Environmental Health Program, as well as any resulting

actions to address unacceptable health hazards identified by those assessments.

2.16.14. Inform the installation Public Affairs office of any violations or follow-up corrective

actions, or other issues, impacting the base populace or local civilian community. (T-3).

2.16.15. Lead the HMMP team and designate a Safety Data Sheet (SDS) gatekeeper to ensure

SDSs not loaded in the Enterprise Environmental, Safety, and Occupational Health

Management Information System (EESOH-MIS) are forwarded to the approved AF EESOH-

MIS SDS Data Steward. (T-1).

2.16.16. For Air Quality and Resource Management:

2.16.16.1. Establish installation-level procedures to document compliance with 40 CFR

Part 51, Subpart W, and 40 CFR Part 93, Subpart B, for those installations located in areas

that have been classified as either nonattainment or maintenance. (T-0).

2.16.16.2. Conduct air quality EIAP assessments required by 32 CFR Part 989 and using

guidance in this manual. (T-0). Supplemental non-directive guidance and recommended

best practices from AFCEC/CZ are also available in the “Air Force Air Quality

Environmental Impact Analysis Process Guide”. Guide is available on the AFCEC’s

SharePoint® site, “eDASH,” accessible via the AF CE Portal.

2.16.16.3. Ensure the installation Air Emissions Inventory (AEI) and Potential-to-Emit

(PTE) emissions are explicitly documented as required, periodically updated, and reflected

in the installation’s specific SIP emission budget, consistent with 40 CFR Part 70. (T-0).

Installation baseline emissions inventory can be used to determine if proposed physical or

operational changes to stationary sources require “netting” or offset requirements under

New Source Review and other CAA programs.

2.16.16.4. Ensure air quality compliance and resource management-related data are

verified and maintained in the standard AF-approved tracking system, APIMS. (T-1).

Included is data needed to build the AEIs; operating permits data, air emission source

information (key top emitters by source categories such as internal combustion engines and

boilers/process heaters); compliance data; vehicle inspection and maintenance

certifications; and other pertinent air resource management information including

decomposition of permit requirements and associated checklists.

2.16.16.5. Ensure owners/operators of air emission sources have operational procedures

in place to maintain compliance with required maintenance and work practice standards

from statutory requirements such as 40 CFR Part 60 and 40 CFR Part 61, National

Emission Standards for Hazardous Air Pollutants under the CAA. (T-0).

24 AFMAN32-7002 4 FEBRUARY 2020

2.16.16.6. Initiate and submit air quality related proposed NSEs under 40 CFR Part 1068,

General Compliance Provisions for Highway, Stationary, and Non-road Program, Subpart

C: Exemptions and Exclusions, for suspending compliance requirements which restrict

military mission and training needs to AFCEC/CZ for verification and processing. (T-1).

The approval of the NSE will depend on the extent to which national security could be

compromised. Once validated by AFCEC/CZ, the NSE will also be coordinated with

AFLOA/JACE before being processed for final installation approval and external

submission, if applicable. (T-1).

2.16.17. Environmental Inspection Process: Conduct periodic compliance self-assessments in

accordance with AFI 32-7001, using shop-level and programmatic inspection checklists, and

document inspections and findings in the APIMS (air quality non-compliance findings) and

the Findings Tracker tool on the AFCEC SharePoint® site, “eDASH”. (T-1).

2.17. Installation Staff Judge Advocates (JA), or NGB JA for ANG and MAJCOM/JA for

AFRC, will:

2.17.1. Report all enforcement actions (EAs) and host nation EAs to AFLOA/JACE, the

MAJCOM Staff Judge Advocate (SJA), and the appropriate environmental organizations in

accordance with AFI 32-7001 and AFI 51-301, Civil Litigation. (T-1).

2.17.2. Review draft permits and proposed federal, state, and local rules and protocols and

provide comments to the Installation Environmental Element. (T-1).

2.17.3. Coordinate permit, enforcement action/host nation enforcement action, and other

documents and actions involving government regulatory agencies with the MAJCOM JA and

AFCEC/CZ. (T-1).

2.17.4. Request approval from AFLOA/JACE (through the MAJCOM JA) for any settlement

where the terms include provisions for the payment of fines or supplemental environmental

projects. (T-1).

2.17.5. Provide consultation for appropriate aspects of the installation environmental

compliance program (to include permits, compliance requirements, and funding) and

coordinate with the MAJCOM JA, as appropriate. (T-1).

2.17.6. Assist in negotiating environmental compliance permit limits and operating

performance measures, and any appropriate agreements with regulators, in close coordination

with the Installation Environmental Element. (T-1).

2.17.7. Ensure that the proper AF “Responsible Official,” or similar designation, certifies state

and local permits and other legally required documents consistent with Title V of the CAA.

(T-0). Certification responsibility cannot be delegated.

2.18. The Air Force Institute of Technology (AFIT) Civil Engineer School will, in

coordination with AFCEC/CZ, provide educational/training programs in support of

environmental compliance, pollution prevention and hazardous material management. (T-

1). Consult with AFCEC and ANGRC SMEs and AF/A4C on environmental course content, policy

matters and target audiences.

AFMAN32-7002 4 FEBRUARY 2020 25

Chapter 3

HAZARDOUS MATERIAL MANAGEMENT

3.1. General Requirements - Hazardous Materials Management Process

(HMMP). Hazardous materials management responsibilities are distributed across the core AF

functions of Acquisition, Logistics Readiness (Transportation Cargo Movement and Materiel

Management), Maintenance, Civil Engineer, Surgeon General, Safety (SE), and Contracting. The

Hazardous Material Management Process coordinates these distributed functional activities and

responsibilities to enable effective AF enterprise-wide hazardous materials management and

oversight. Any unit that uses hazardous material (HAZMAT) must be supported by a HAZMAT